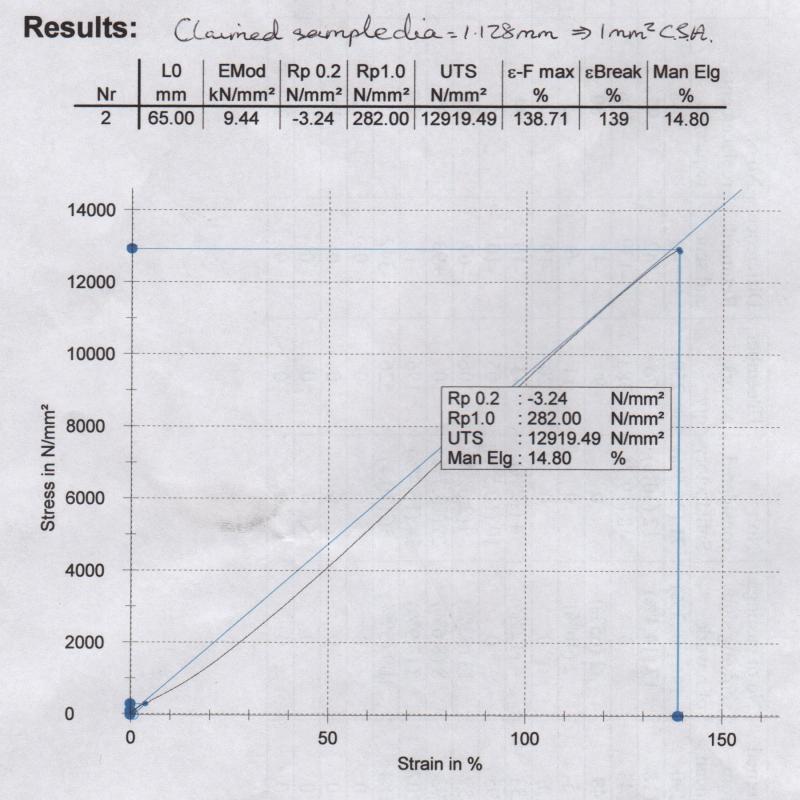

Practical point for tensile plots. Because materials scientists think of "stress" (force/unit-area), the computer-controlled tensile tester insists on outputting stress. It took until a couple of tests gone by to realise that if I dishonestly told the testing machine my sample is 1.128mm diameter (thus cross-sectional-area = 1mm), it would trick the output plot vertical axis to read the tensile load (force) on the rope in Newtons.

All done on 10mm cut-film polypropylene (PP) 3-strand laid rope. The cheapest rope by a long way. This rope here is literally builder's merchant "disposable" rope.

I'll try to do a bit of background on this. Cheapest is an advantage

not to be sneered at. If the rope is showing signs of wear-and-tear,

you can freely replace it with a fresh length. Greatest safety

advantage you can have...

Also, you can twist open the lay of a 3-strand rope to inspect its

condition; which you cannot do with a braid, whose internal condition

is inaccessible. Appropriate for material lifts with harsh usage.

The tensile test sample (lower) and broken tested sample (upper) look as follows:

(not the actual samples for the tensile test result presented)

The plain rope samples were carefully spliced with 690mm between

centres of fingers when rope pulled tight through eyes.

This 690mm length fitted the tensile tester best. Knotted samples

where formed with the same centre-to-centre distance

Force matches scale on vertical axis. Break force is 12919N.

The rope had elongated 90mm at break, which is 13% elongation on the

690mm original length.

The crucial point here, enabling all knot and splice tests, is that rope broke in middle. That is, the eye-spiced ends give full-strength terminations in tester. See pictures elsewhere of other observations about the test.

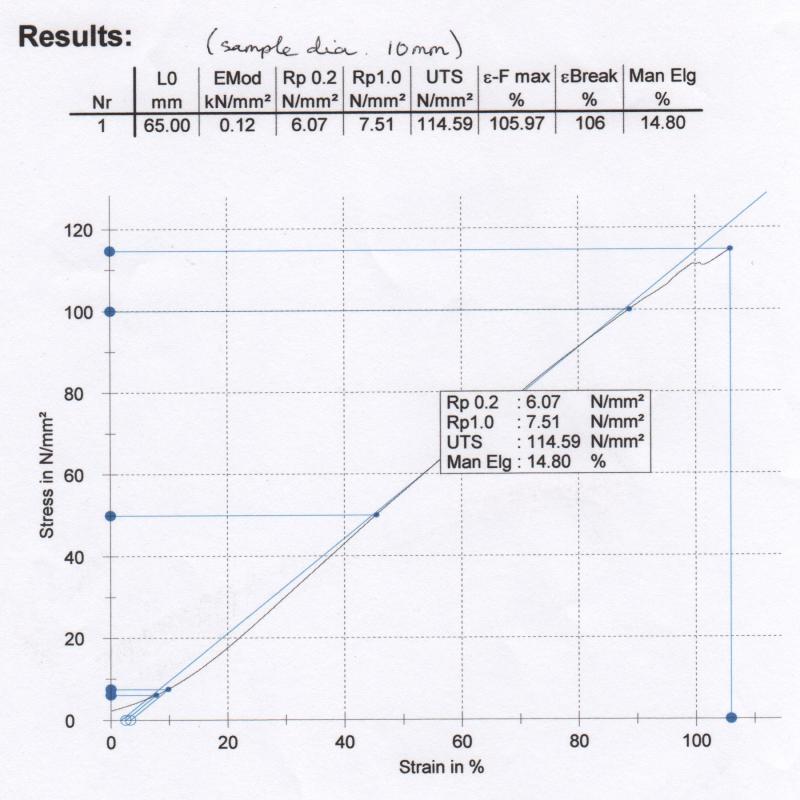

The is from pre realising declaring sample dia as 1.128mm gives useful

outcome. Hence vertical scale not useful without conversion. Have calculated:

Break is at 9028N, which is 920kg-force.

This means the Fisherman's knot is keeping 70% of the rope's strength (using the break strength of a plain length of rope just reported). Which indicates what you use this knot for. If you quickly need to join ropes and you want all the strength you can get. You can't easily get a fisherman's knot apart after it's been loaded, by the way.

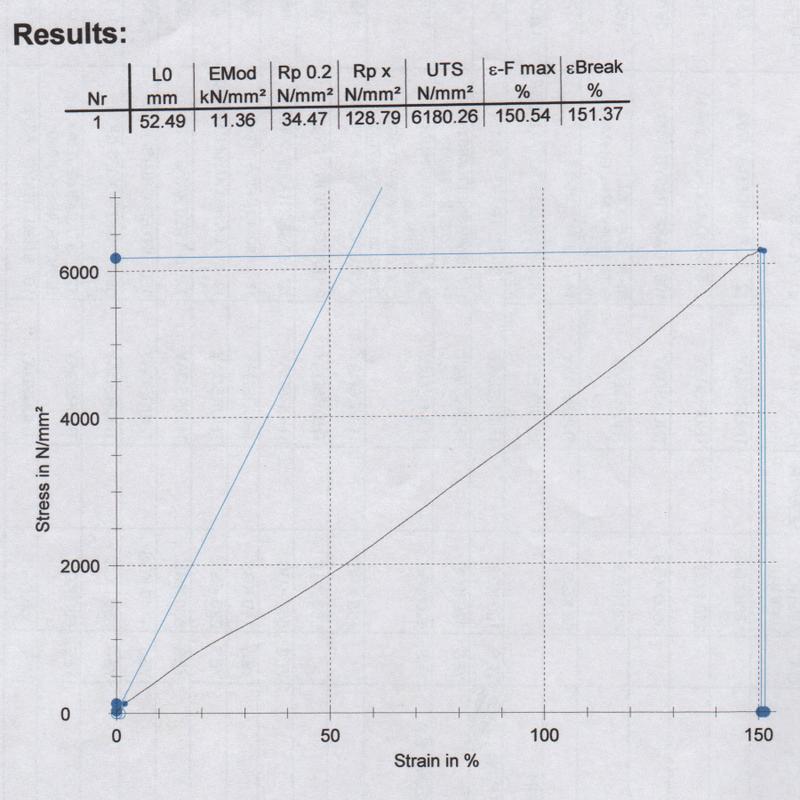

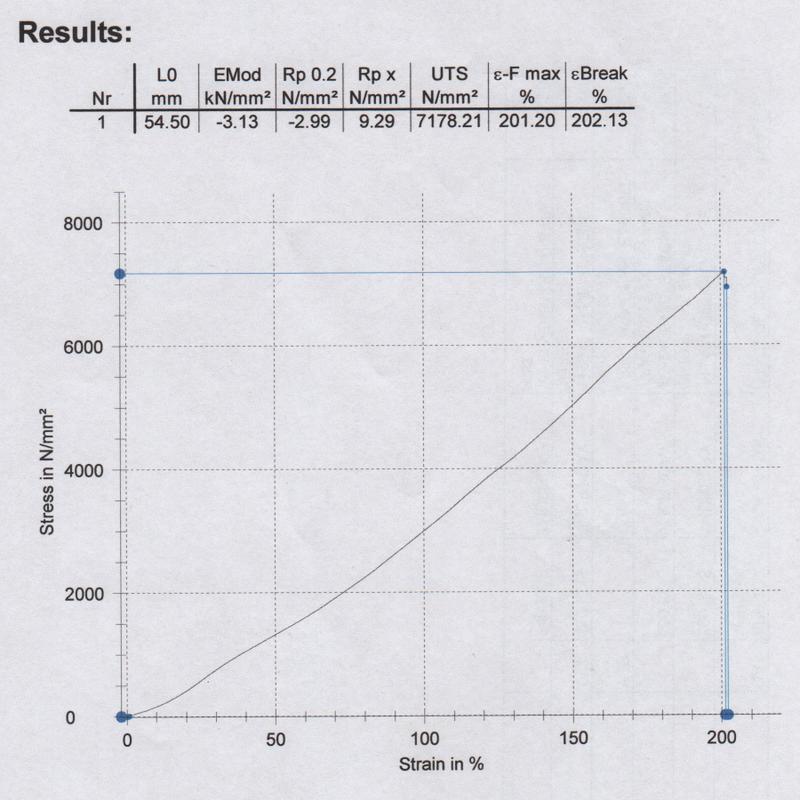

The Carrick Bend can always be undone after loading, yet the Carrick Bend is rated as very secure.

Sample under test

Two tests performed:

Tensile results are 6180N (630kg-load) and 7178N (732kg-load). These give estimates that the Carrick Bend confers 48% to 55% of the rope's strength.

This fits with the general claim that the any knot reduces the strength of a rope to a half of its strength with no knot in it. Another way of putting this is that the efficiency of this knot is about 50%.

The surprise is to see the strength of this rope. In normal construction work you never ever see the contracted elongated appearance of these ropes in test. The upper 90% of the tensile test plot to break is never ever seen. All normal usage is in the initial 10% where the rope is still "loose construction" and rapidly extending with load. The high-load elongation and contraction of diameter leaves a much shallower twist to the rope which is a shock to see.

The knots do reduce the strength, but those strengths are still very high. The safety margins in actual use are enormous. We know that, but seeing this evidence is awesome.

The break is with a very loud bang, accompanied by a hot aroma and the knot is warm to touch. More awesome observations.

That an eye-splice gives a full-strength termination amazing to see and useful to know. If you can organise a rope-run without knots and where the rope does not touch any sharp edges - a sort of perfect condition - you can get double the break strength and presumably much higher jolt resistance.

Tests on a short-splice are shown elsewhere. It was not possible to know their ultimate properties because slippage of the strands as the splice bunched-up in the middle under load used up all the travel of the tensile tester. Hence no test result.

The Fisherman's knot proves itself where loading will not be polite. In reality, you can always cut off the knot when the job is done, loosing about 300mm of rope per occasion. In all normal situations, for the price of this rope that's not worth a moment's consideration.

Then the Carrick Bend shows itself as the one to go for when loading is moderate and well-controlled. With being able to freely tie and untie a Carrick Bend.

R D Smith, 08May2011