Another weld developed by the author for a client. Good by a huge margin.

This fillet weld on 10mm thickness plain steel ("carbon-steel") is

This welding condition is very "robust".

("On a bad day you get a good weld. On a normal day, you get an ideal

weld. However, it's the worst weld you can realistically get which

matters...")

Pictures of the tests on the weld demonstrate this.

The weld is very pleasingly productive at 520mm/minute.

The set of tests:

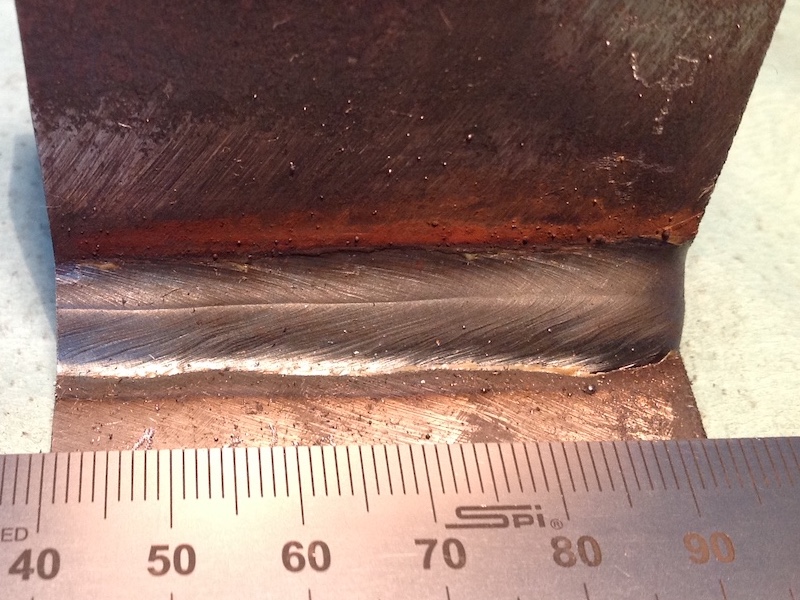

Overall appearance of the test weld:

with plenty of fluidity, so this weld would have ideal strength and

probably an abnormally high fatigue-endurance ("fatigue-life")

Macros - were the test-weld is transversely sectioned, polished and etched

(same sample seen in different lighting conditions):

with more-than-necessary but freely-obtained fillet-corner ("root")

fusion, good shape including perfect weld-toe geometry

and abundant fusion made semi-quantitative to evaluate with scribed

lines "continuing" the plate surfaces across the weld-metal

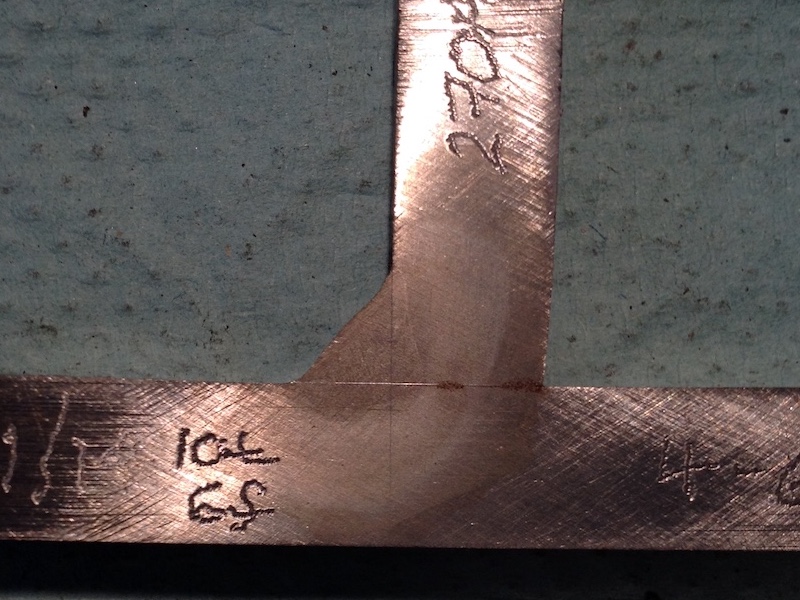

The nick-break tests:

are excellent, showing all very well along a goodly sample length of weld

Above image - fillet-corner fusion revealed by the big "step" where

broken-off part is matched against thickness of plate

is explicitly shown in this following image

Presented as a commendable work-a-day weld, where anyone seeing these welds on components arriving at site to be put into place and used would know they can trust everything on these welds.

(R. Smith, 26May2017)