[ < Mining, Minerals, Geology, etc. | << website root index page ]

Skip load - Condurrow mine

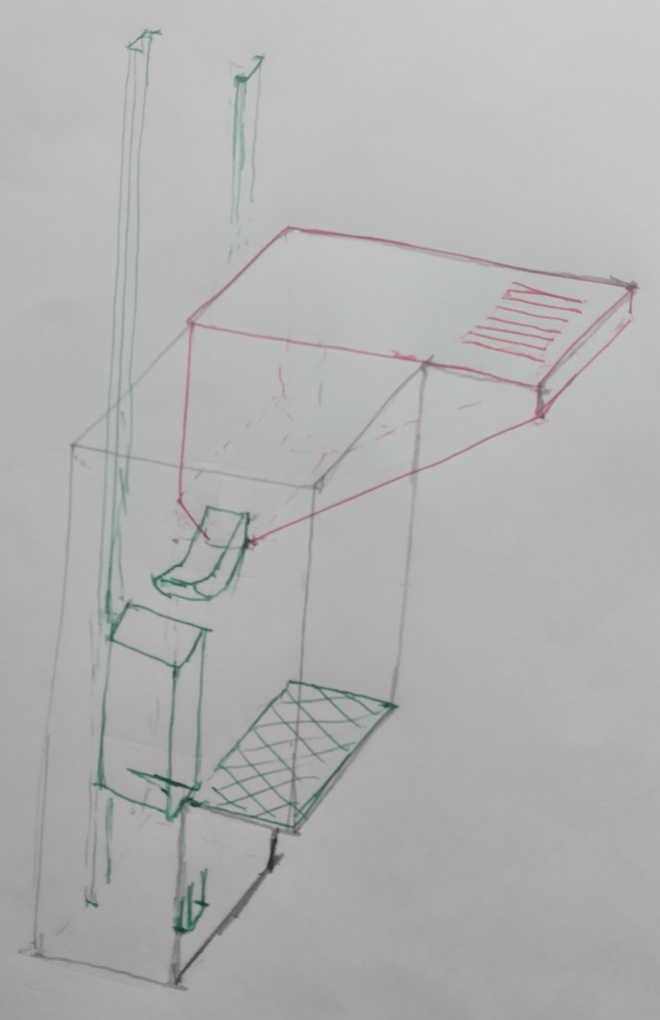

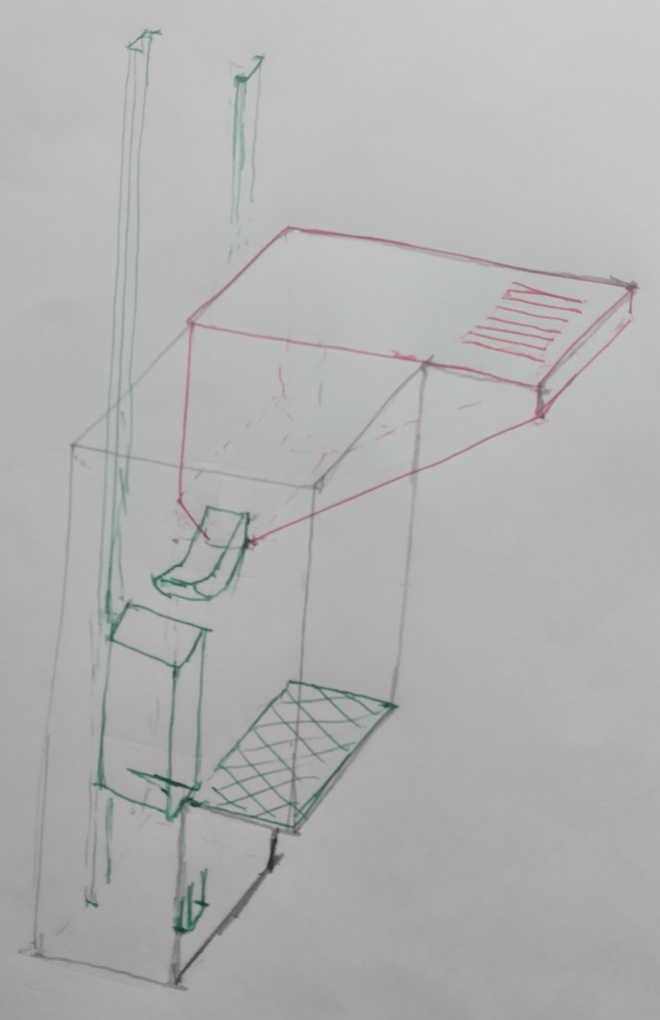

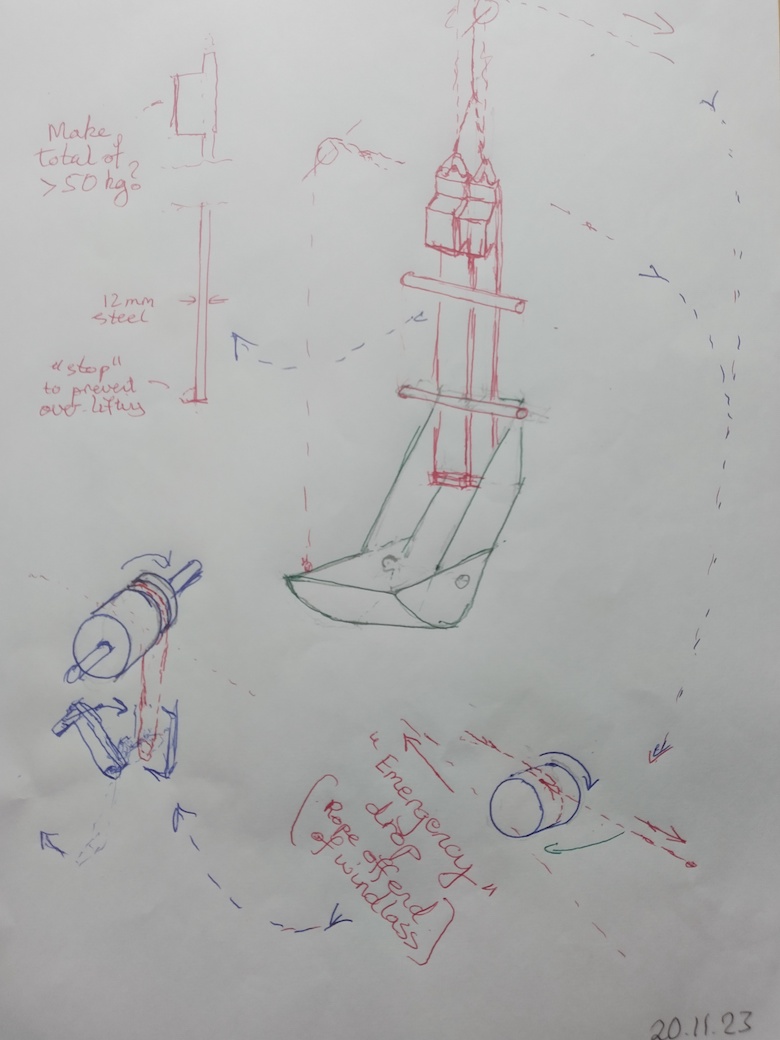

General view of "the loading pocket"

We note:

-

Ore bin at / just-bellow tramming level is shown in red - with

grizzlies indicted

-

Green is the ore chute, skip (ascends/descends the shaft), the guide

rails and the floor of the "loading pocket"

-

Information:

- The skip is about 1 tonne capacity (?)

- the grizzlies stop stones more than something like 125mm size

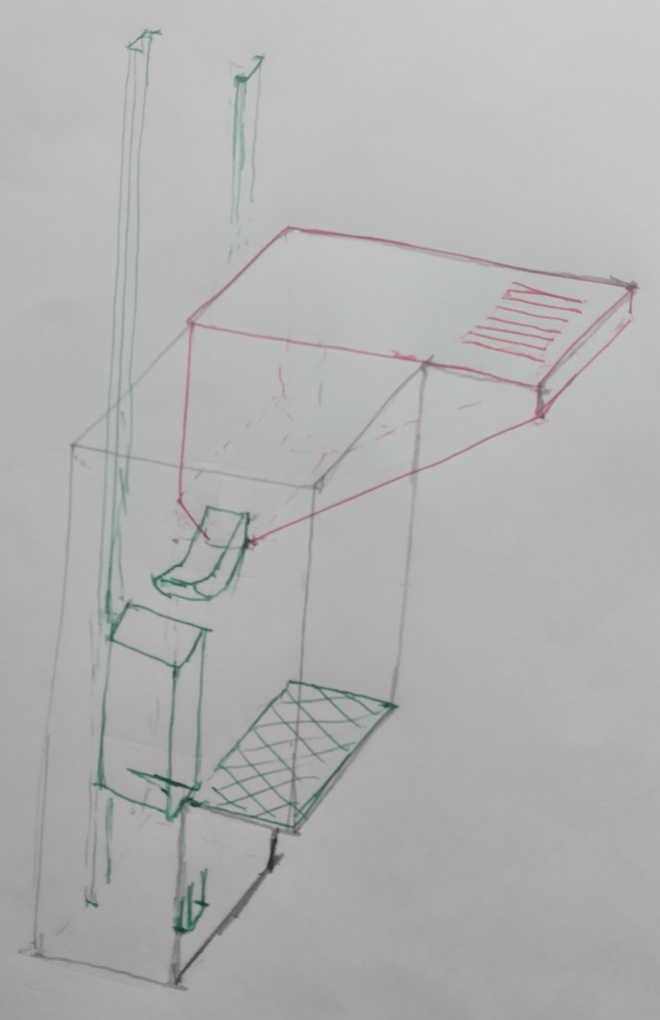

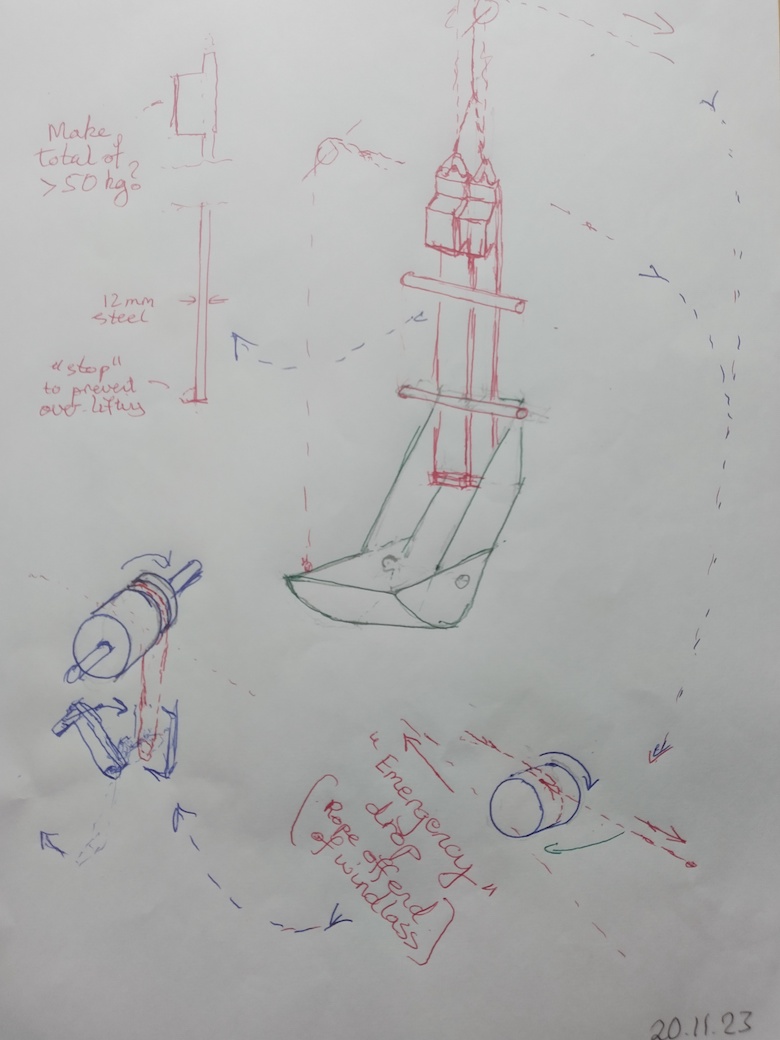

Detailed view of suggested skip loading mechanism

-

control of loading from the tramming level

You can look down from the tramming level to the skip below the chute

and see what is going on sufficiently well (I think yes) ?

-

uses a capstan / windlass system with ropes

-

the "gates" are similar but are plate-steel ("slippery" and strong)

-

the gates are self-closing by deadweight (?) and the action is to hold

them open (they fault to closed)

-

I indicate rope from each "gate" converging - because all is achieved

and there is and cannot be more than one windlass (more than one and

the ropes and winding handles would tangle - and overall be

unmanageable + without advantage)

-

I indicate (previous two points) two side-by-side plates of steel so

if one is jammed by a large stone the other would close and shut off

the flow - however no background informs this and a single larger

plate is an obvious option

-

rotating "tip" of chute is also on a capstan / windlass

-

the ropes are deliberately smaller size and limited strength so in

overload they break - eg 6mm cut-film polypropylene rope is

1/2tonne breaking - so does not risk overloading the pitwork the bits

of the mechanism are attached to - given everything defaults to

safe if the ropes break (okay the tip of the chute would not rotate up

but the flow would be stopped by the "gates" and at worst there would

be a few kg of spillage down the shaft)

-

the common objection to cut-film polypropylene (PP) rope ("disposable

rope") is it degrades in sunlight - and given this is down a mine you

would know what is degraded or never formed is what is on the

objectionist's shoulders

... not withstanding the "faults to safe" and "avoids possibility to

overload pitwork in any scenario" arguments

-

one reason for windlass is you can let go of the tail of the rope and

"that's that" - the gates drop in gravity

If the ropes are tailed by elastic you could still tip the tail of the

rope off the windlass ending the "self-servo" and the gates will drop

-

almost nothing new goes down at the "loading pocket" apart from rope

attachments, everything needed through-bolts to existent timbers

(R. Smith, 20Nov2023, 23Nov23 (links inc. wsroot))