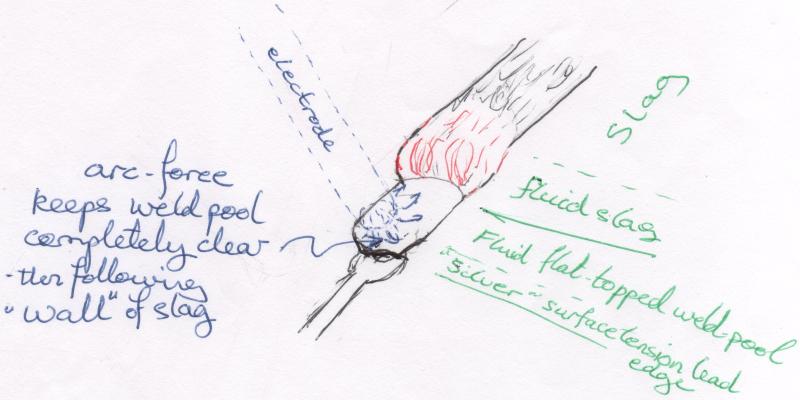

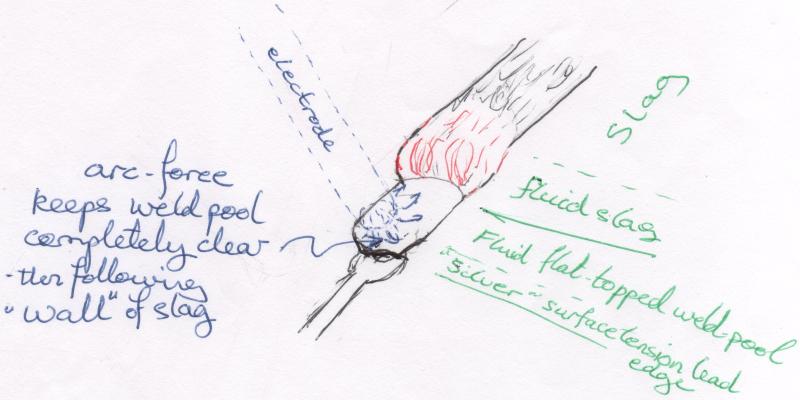

As I understand it, this is a good appearance of the weld pool and immediate surrounds during root-running a single-sided V-butt weld. As you might be doing welding a carbon-steel pipe.

Identifying this came with diagnosing the reason for faults including porosity seen in the radiograph of a 5G weld. This appearance of weld-pool, "the fingernail", is readily obtained in 2G welding and was familiar to me in this context.

In this condition of "the fingernail" you have a properly fluid weld pool with wetting and self-cleaning action, proper arc chemistry with shielding fully formed and an orderly correct flow of the flux / slag to its required locations for metallurgical and shielding purposes.

In recent practice in the 5G position with 10mm wall-thickess 140mm O.D. pipe I found the condition was attainable and the results were good.

Aiming for this appearance of weld-pool, you are now going on appearance of the weld pool and the calibration of the dial on the welding machine is irrelevant. At good conditions the welding machine showed 75A when running 2.5mm-dia "Filarc 56S" 7016 electrodes DCEN.

To calibrate - run b-o-p on 8mm steel, gave a semi-circular cross-section weld bead properly shielded, humped though still correctly running, with bead edge intersecting the plate at 90deg (right-angles).