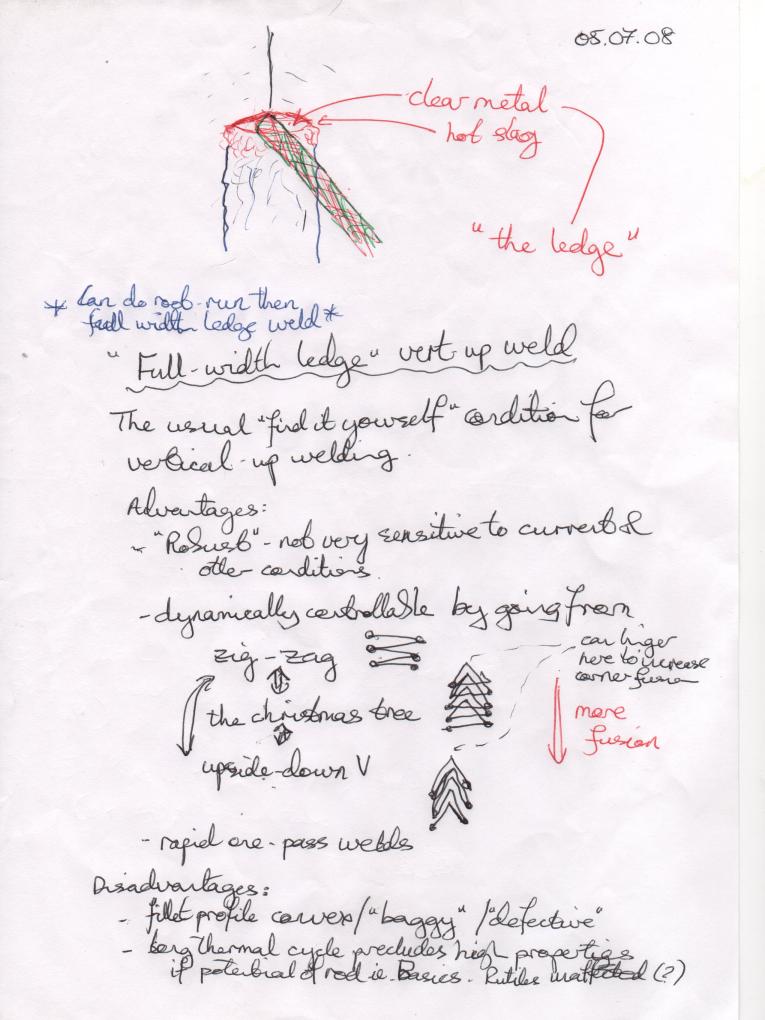

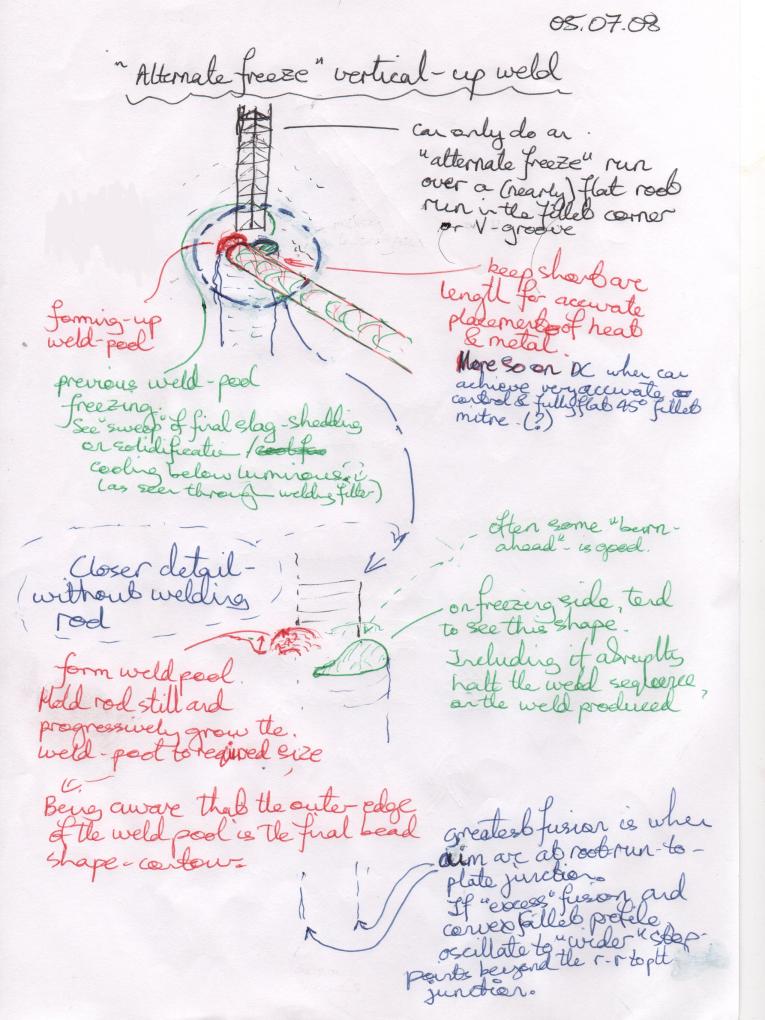

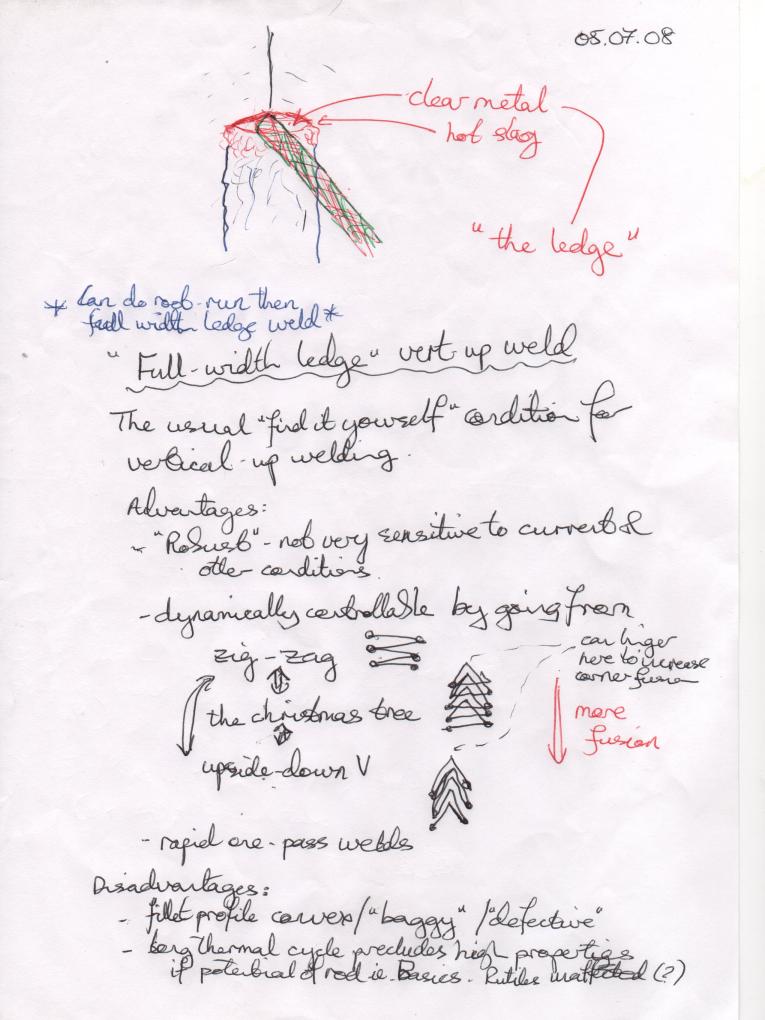

I know of these two different approaches to vertical-up stick-welding. The "full-width ledge" is condition-insensitive and is generally more productive. However, the "alternate-freeze" method is needed for "nuclear power station" spec welds. (create engineering-stress-preferable flat smooth 45deg mitre weld bead shape; rapid weld-metal freeze to get strength + toughness (?)).

The "full width ledge" method is what you'd arrive at if you are a good downhand (UK speak - that means "in the flat position" and "hori-vert fillet") welder and tried to improvise a reasonable vertical up weld.

The "alternate freeze" method means you have about a quarter of the amount of liquid metal at any one time, and is a totally unfamiliar operating condition if you are practiced at only "downhand" (UK-speak) welds. You need a very stable welding power source (?). You'll end up understanding about quality of welding machines...

My practice comes mainly from using 6013's / Rutiles and you should be aware that there might be some "slant" in the following illustrations reflecting this. However, I've seen the "alternate-freeze" method done with 7018's / Basics for "nuclear power station spec" welds and can produce a reasonable "alternate freeze" vert-up T-fillet with 7018's, and wouldn't flag up any profound weld manipulation differences...

With Rutiles, they do seem to like being run on DCEN, giving a very consistent smooth burn, negating for vert-up any potential penetration advantage of DCEP for anything except unprep'd seam-welds (?). Differences between using DC and AC are mentioned - see index to learning SMA welding pages.