Waveform analysis for MIG / GMAW "dip-transfer" mode

These welds were performed on 5mm steel plate with 1.2mm diameter steel MIG wire and Ar/20%CO2 shielding gas.

Sample rate 10kHz

(10thousand measurements of V, I and wire-feed-speed

recorded every second).

Dip transfer - a common representative condition

180A 18.7V

A current of 180A is at the top of the range in which dip-transfer is

used, according to contemporary practice (writing in 2017).

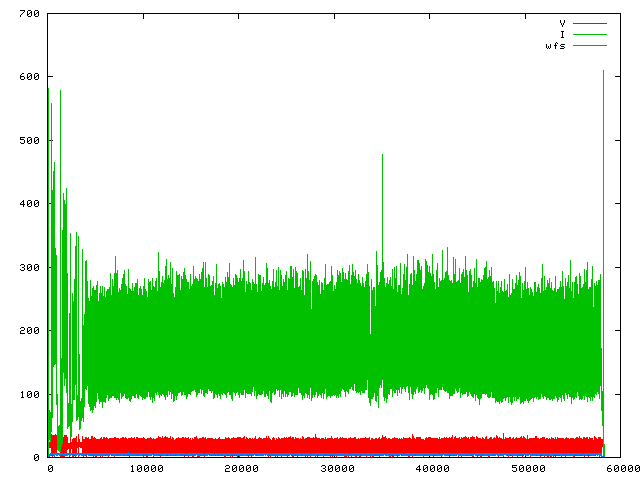

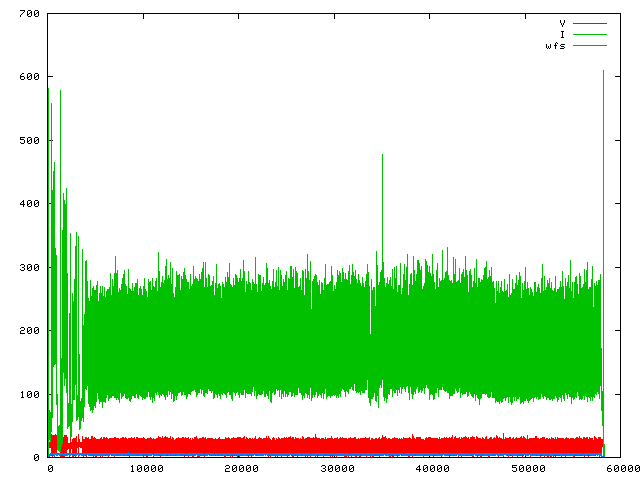

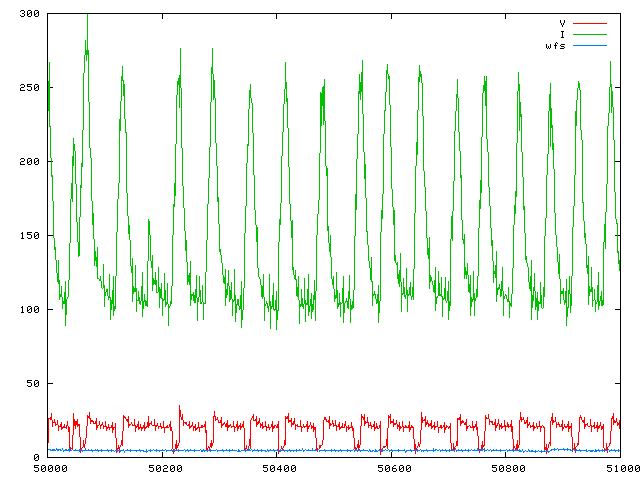

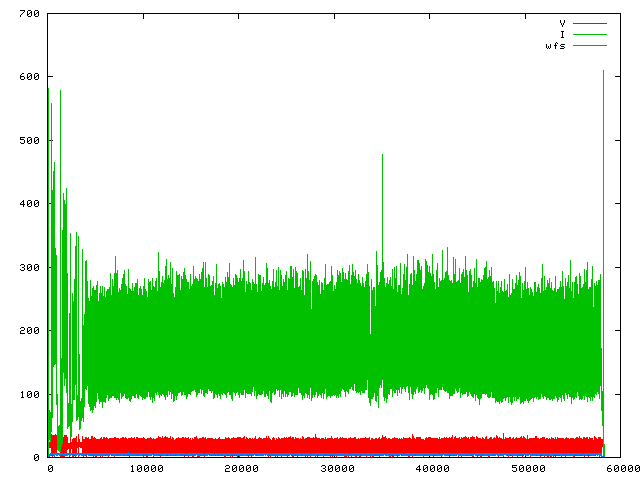

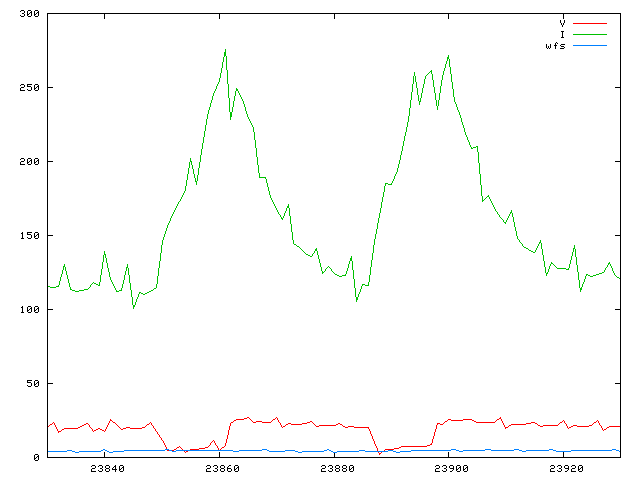

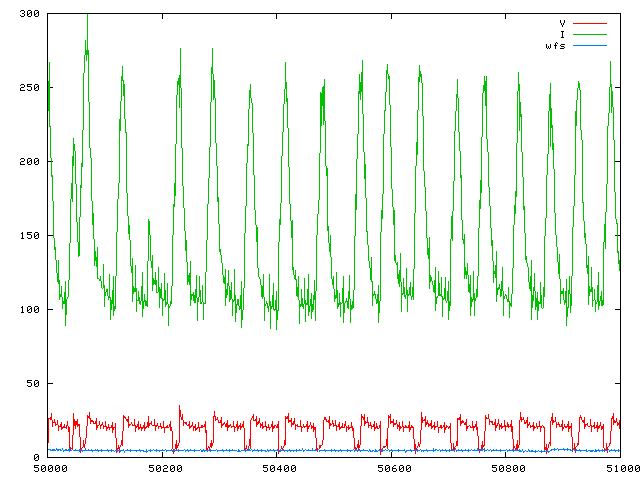

Overall view

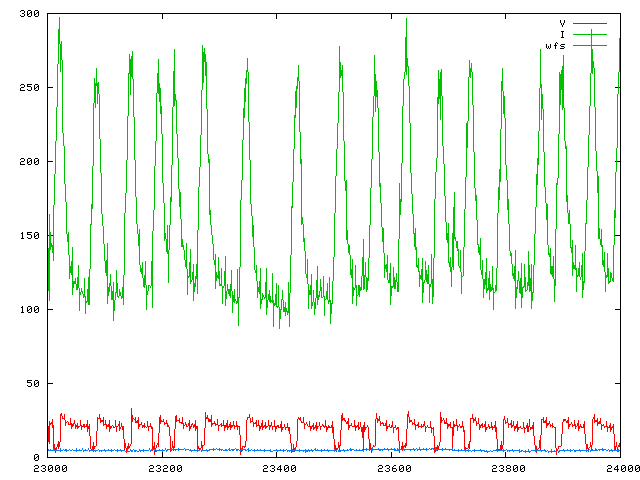

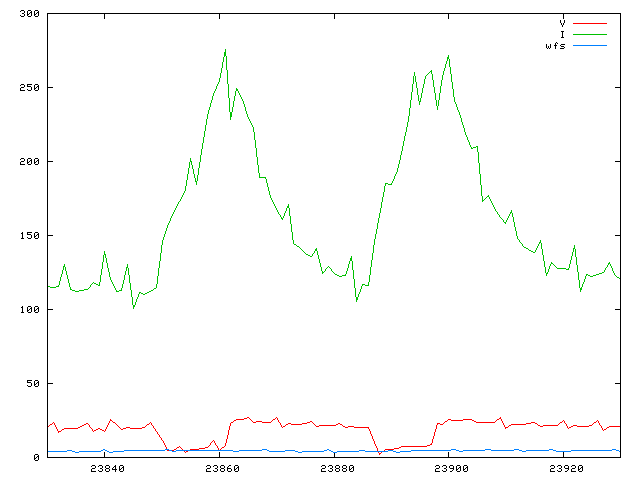

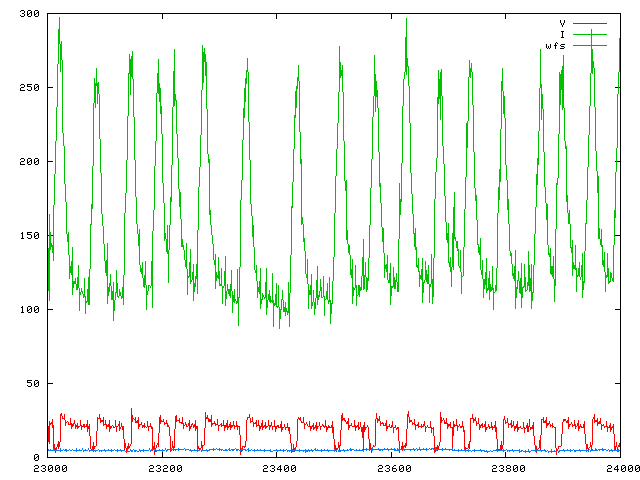

First sample - 0.1s and 0.01s

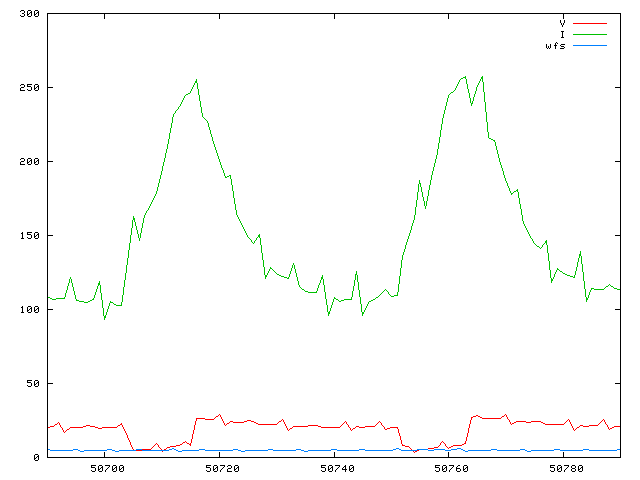

Second sample - 0.1s and 0.01s

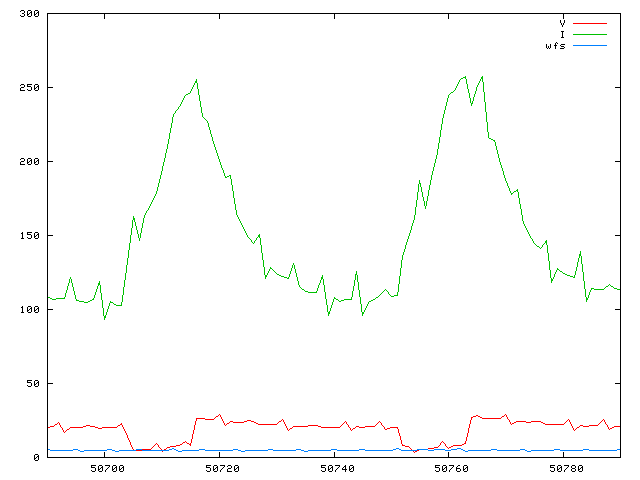

Fairly much as expected. Assuming zero-volt regions are duration of

"dipping"/short-circuiting:

- the "dipping and arc'ing" is indeed cyclical at a rate of about

180 per second

- "short-circuiting" ("dipping") visible - volts go to near-zero for

~1/1000th of second (around +4.5V - the Ohmic V-drop?)

- current rise - with steady upward slope during the "dip" (the

short-circuit) due to inductance (or simulation of by inverter power

source)

- current fall - with steady down-slope when "dip" breaks also due

to inductance (or simulation of)

- voltage sustains at an arc voltage as current stabilises to around

120A for arcing phase

The dipping action seems very regular and well-behaved.

Other datalogging performed indicates this example shown is

representative.

R D Smith, May&June 2011, 12Jun2017