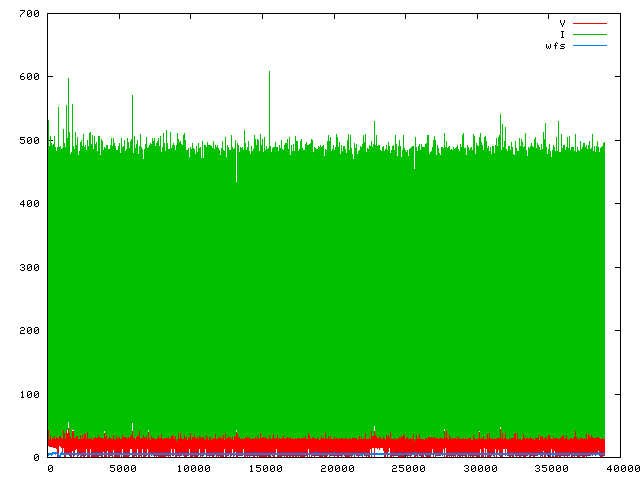

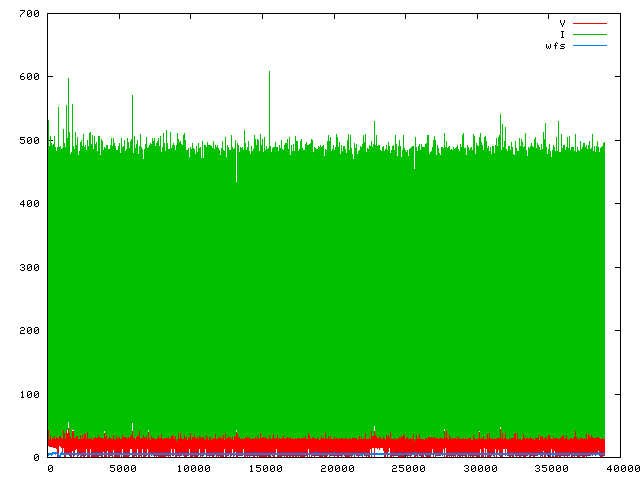

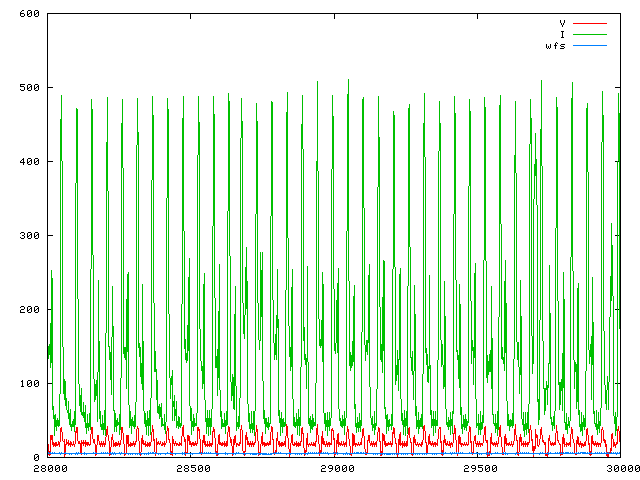

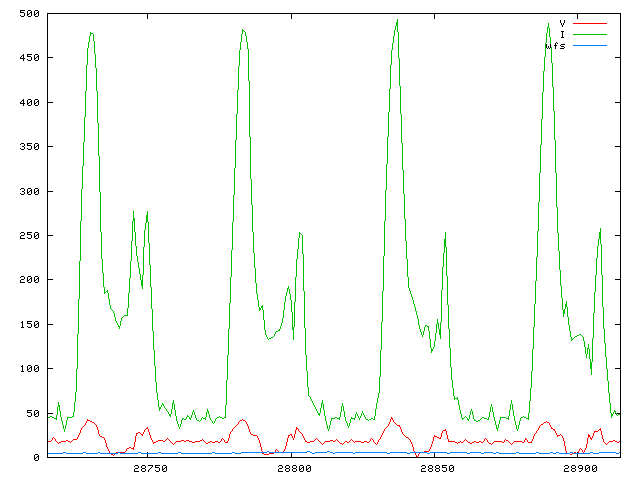

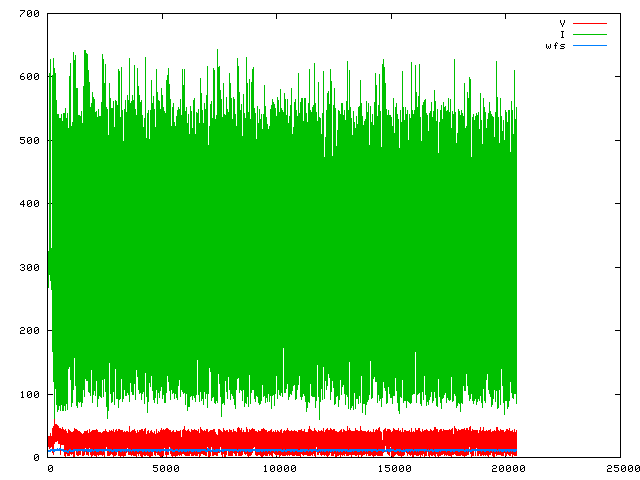

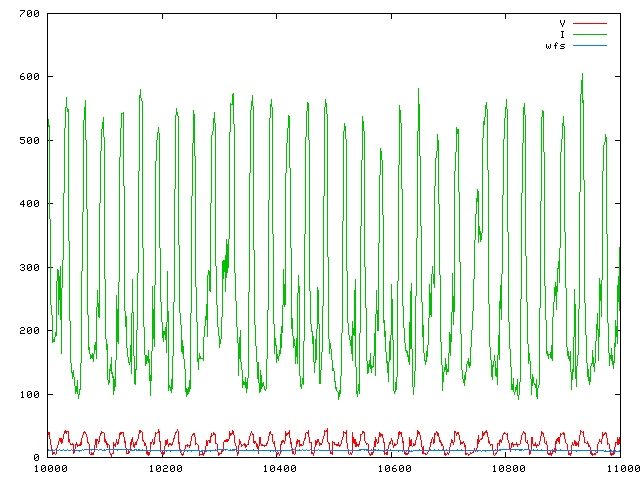

All traces / graphs are for Lincoln Electric's "RapidArc" - a variant of Pulse-GMAW claimed to give stable welding at fast run rates.

These welds were performed on 5mm steel plate with 1.2mm diameter steel MIG wire and Ar/20%CO2 shielding gas.

Sampling rate for all data-logging shown here is 20kHz.

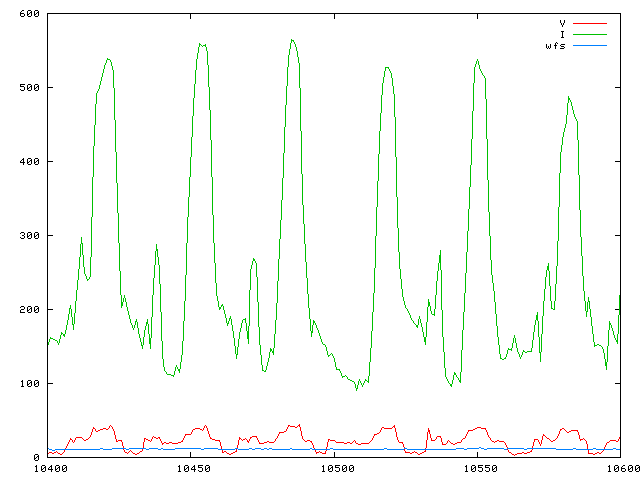

The intended low-voltage event is seen. This was described by Lincoln as being a necessary part of the cycle, enabling a very short controlled arc-length which they say (very plausibly) makes the high run-rates possible - with no spatter...

The brochure description of "RapidArc" is compatible with the waveform measured. The second small current peak does indeed look to be designed to depress the weld-pool away from the wire when the short-circuit breaks, as claimed in the brochure(s).

Fast controllable welds with no spatter.

139A 19.9V

247A 23.2V

R D Smith, 26 May 2011