Abbreviations used

The question is whether the 8mm thickness of the "horizontal" Rectangular Hollow Section is "insufficient" for the forces and the plate is deflecting in rotation?

With this being the virtual world of numbers in Finite Element Analysis modelling, the easy answer is to make a copy of the BCFWTT model but where the thickness of the Rectangular Hollow Section is increased to 15mm. Then see how it behaves. If there were a case for the change, one would probably weld in an insert of a good-quality 15mm thickness steel where the RHS butts against the vertical plate and the weld is deposited. But first - let's look at the case, with FEA...

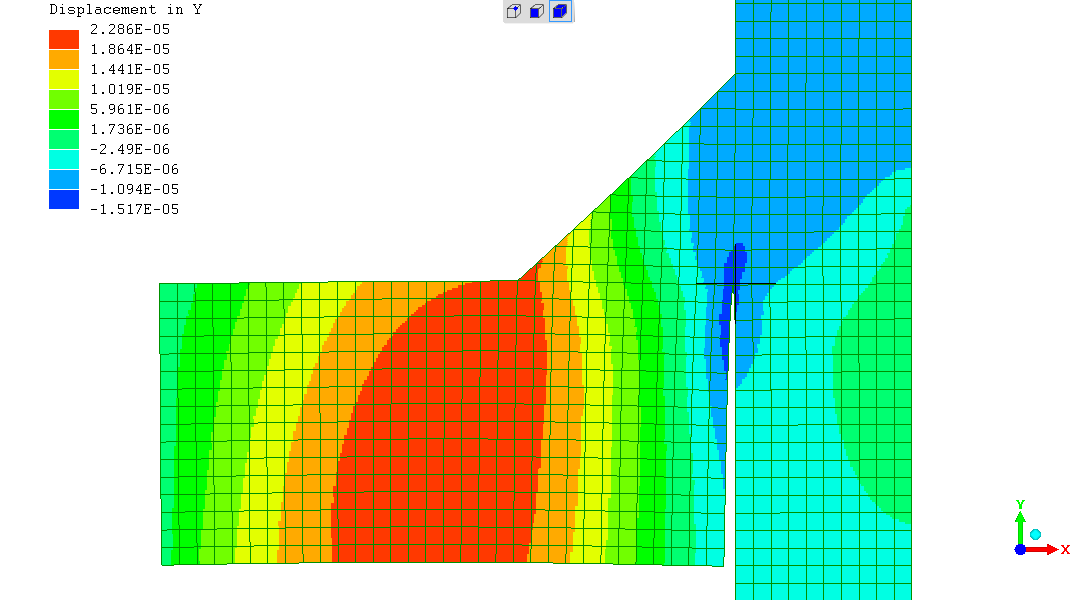

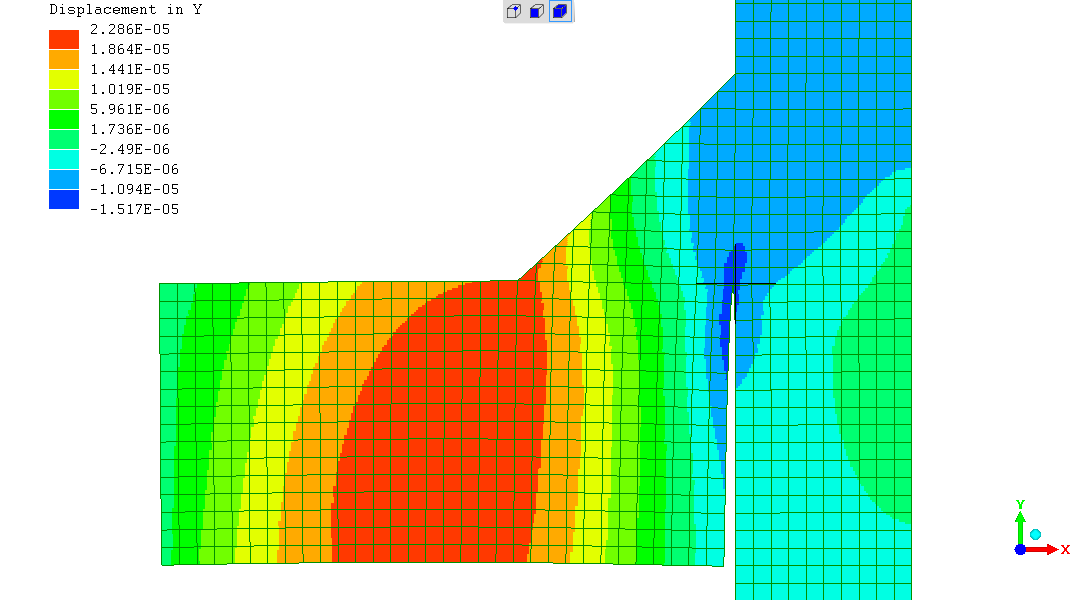

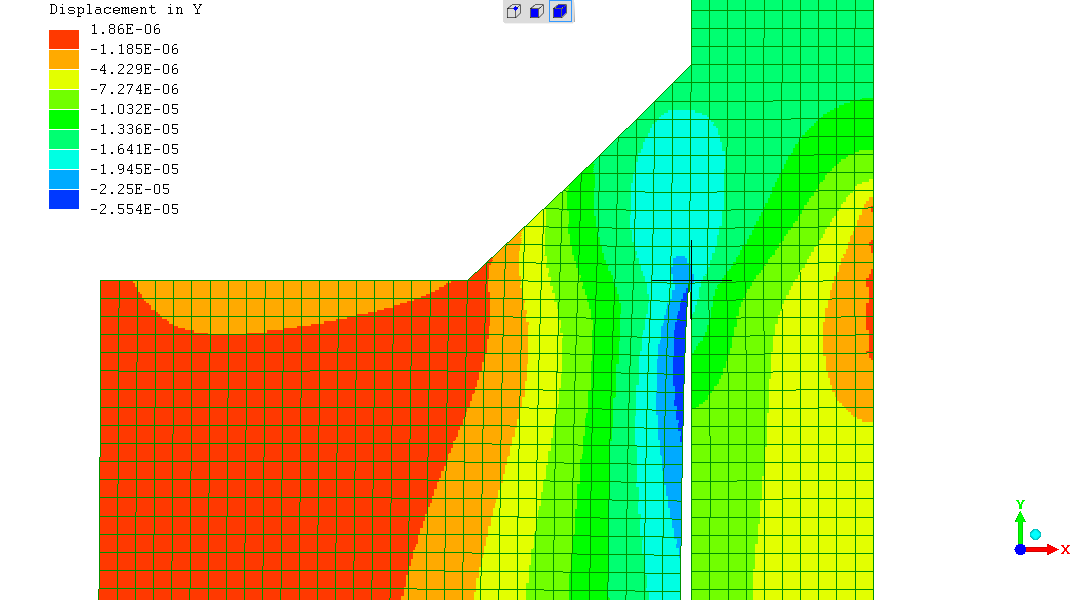

Rotation about the "z" axis was unavailable - but displacement in "y" presents the same impression.

8mm thickness RHS

15mm thickness RHS

The increase in the thickness of the horizontal plate from 8mm to 15mm reduces the deflection to about a 12th.

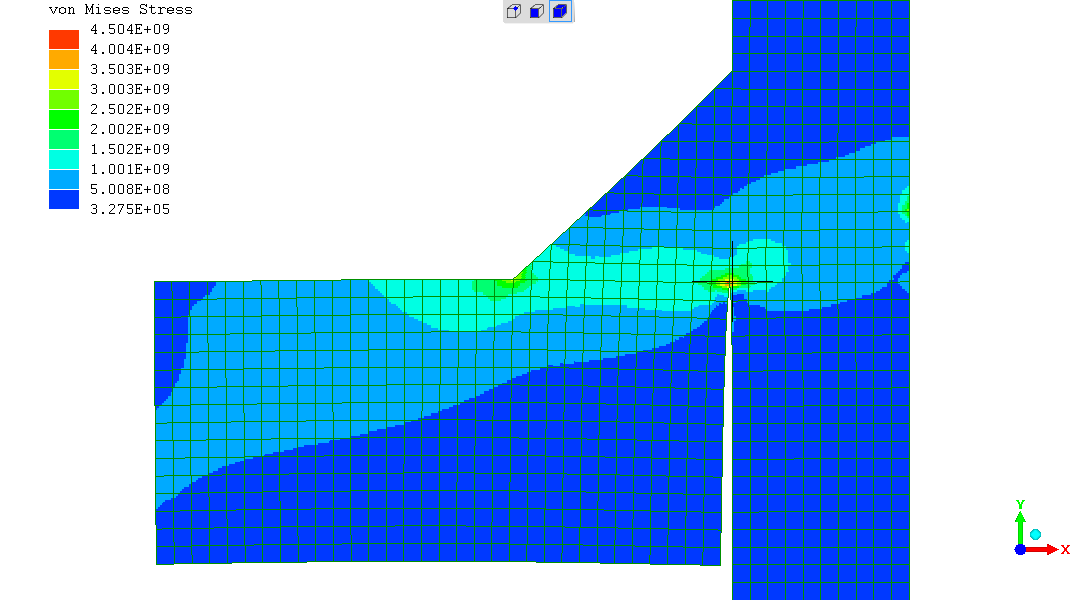

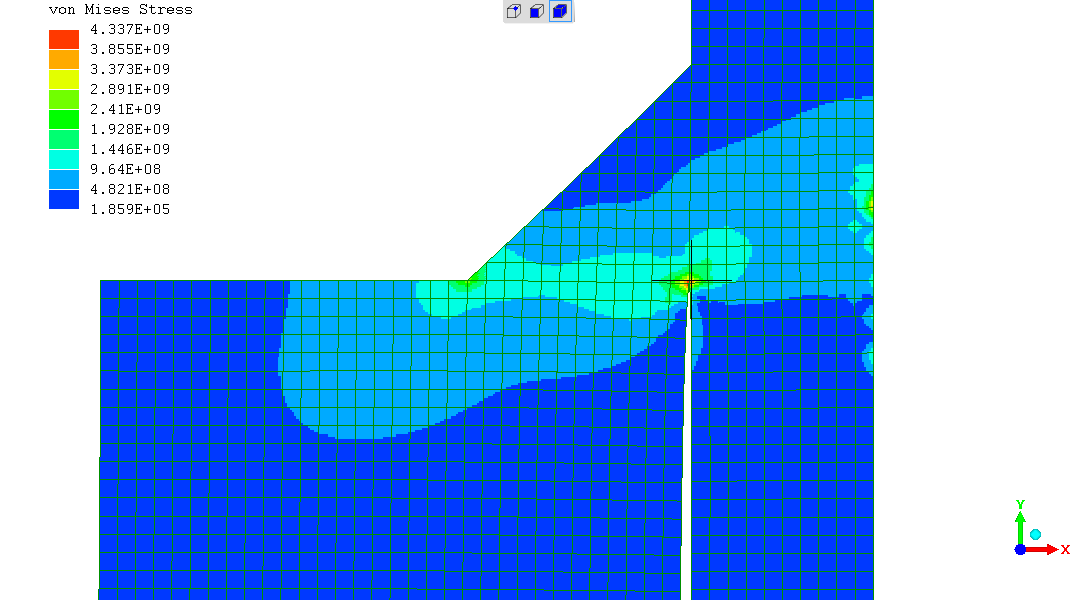

8mm thickness RHS

15mm thickness RHS

The von Mises stress at the fillet corner and elsewhere is barely affected, with a slight reduction of around 4% in stress going from 8mm thickness to 15mm thickness of beam adjacent to the vertical "middle" plate.

So the impression is that there is no problem with the thickness and stiffness of the RHS as specified, at 8mm thickness, for a 6mm leg-length fillet.

(R. Smith, 06Feb2021, 07Feb2021 (edits))