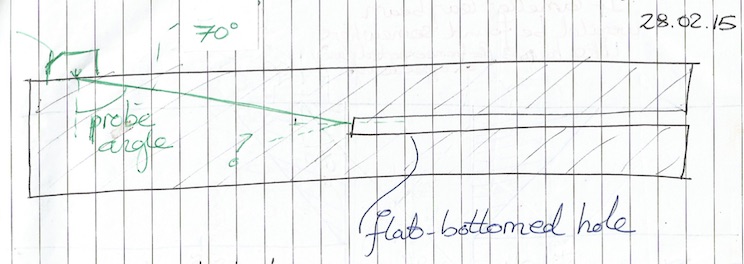

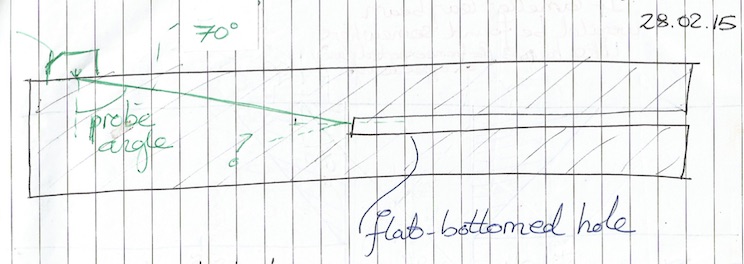

The Subcontractor proposed using Ultrasonic Testing with a 70degree shear-wave probe to demonstrate the absence of planar flaws transverse to the surface.

I was sceptical. My instinct was - you would see nothing on the UT-set screen at any location, even if there was a large transverse defect there.

The challenge which I set - demonstrate to us that a 70deg UT probe "sees" transverse planar defects...

I sketched this test-block - made using a broaching tool in a magnetic-based drill (eg. "Rotabroach") which is always available in an steel fabrications workshop. A broaching tool has a "flat" end, so a "blind" hole drilled down the block's length will present a transverse planar surface.

To the physics of UT examination, it is irrelevant whether a planar reflector is a crack or a surface - hence the challenge is representative.

The nub of the issue is - how does the echo off the "defect" - the transverse reflector - return to the probe, to be detected?

The green question-mark represents my question - where does the reflect beam go?

The case was compelling, and the subcontractor had to instruct their Non-Destructive Examination contractor that the test must happen.

The subcontractor found some 50mm square steel and had the hole drilled.

Here is the test-block, alongside a block with no feature.

The subcontractor's NDE contractor could not demonstrate detection of the transverse reflector, sliding the probe around the block's surfaces...

With representatives of the other project stakeholders looking on, there was no difficulty convincing that another NDE technique was needed.

(R. Smith, 03Nov2016, 20Apr2017)