At the manufacturing site, I'd rejected the Radiographic Testing method presented as a documented procedure, showing to the satisfaction of all that it would have at an insufficiently high resolution of defects.

A solution was immediately needed.

A local expert ("Level 3") in Radiographic Testing was engaged. This is the technique arrived at.

I suggested a 1mm Se75 source (a radioactive isotope) might have offered the best result, showing the case according the applicable ISO Standard for Radiography - but none was available then in that country (you cannot readily carry a radioactive isotope source across a National boundary).

This method was a fusion of what the local Radiography expert was trying to think his way through, with me pointing out that we could borrow the welding positioners the component had been welded on - which made the approach readily achievable.

It uses an industrial X-ray set available in a concrete bunker in a nearby aerospace facility.

This radiography solution would give high quality (being Single-Wall

Single-Image (SWSI)) but be very inefficient, needing 20 accurately

positioned radiographs to get around each butt-weld. With two

butt-welds, one at each end, to radiograph, that might seem infeasible

for this 700kg delicate component.

Except...

By borrowing the welding positioners and taking them to the

radiography bunker, we could have the X-ray head in a static position

and easily rotate the component increment-by-increment upon the

welding positioners.

I had my Basic Radiation Safety certificate, so helped-out on the day doing the radiography.

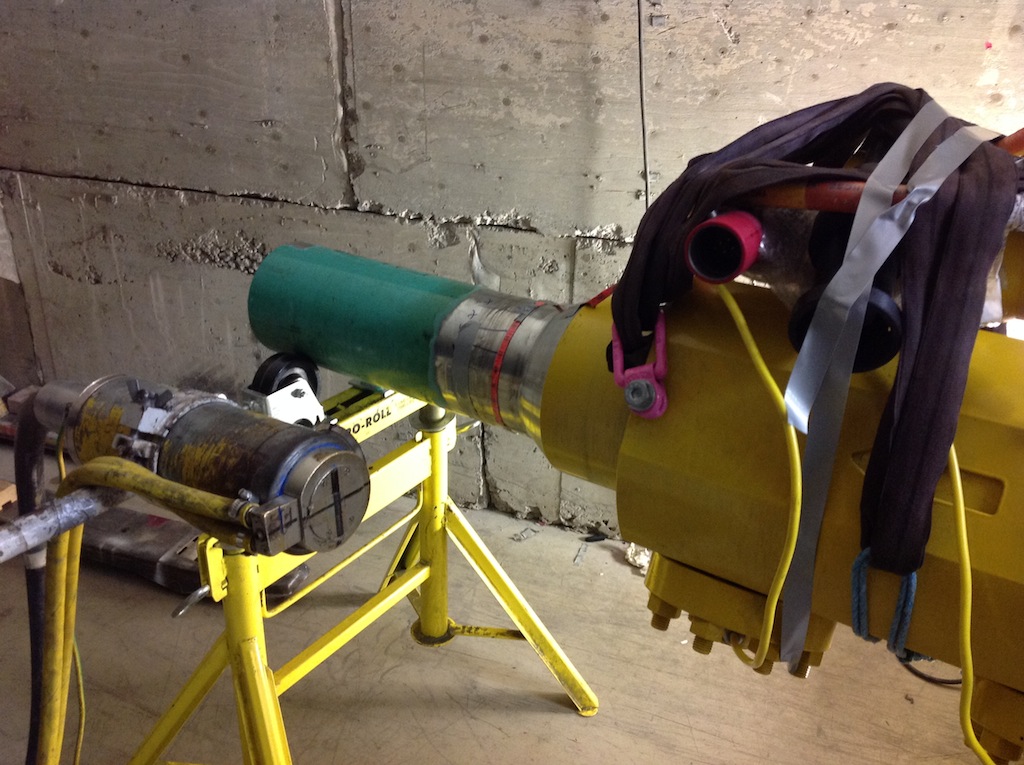

General view

Closer view of the X-ray head and "optics". The

lead-number-distance-tape (red) around the circumference casts a

location-identifying shadow on each radiographic film obtained. The

marker-pen marks help the person quickly rotate the component to the

next shot, making for a simple quick consistent repeated sequence to

simplify safety management.

A piece of sponge firmly pressed the radiography film close up against

the bore of the tube/pipe.

The grey fabric-reinforced tape holds the Image Quality Indicator in

position - on the source-side.

The radiographs had excellent quality and resolution, giving confidence in the weld quality.

(R. Smith, 21Oct2016, 03Nov2016)