I have found Radiography a very interesting subject for the layers of understanding needed in its practical application. The "Tradesperson's knowledge" necessary to do radiography to good effect. There is no physics here. All is about the circular relationship between practicalities, choices and ramifications.

I suspect many will have to take it on trust that these following examples are "fascinating"!

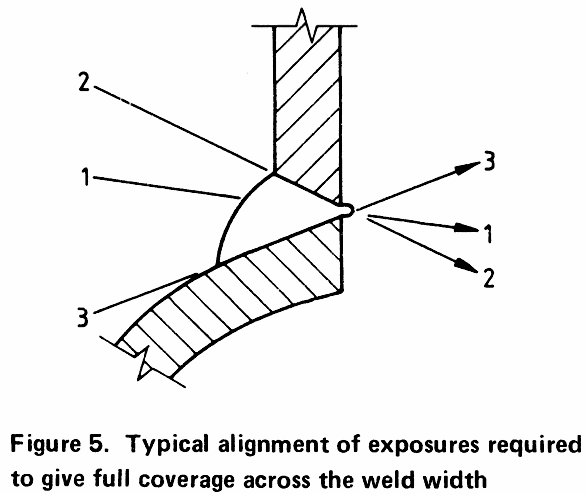

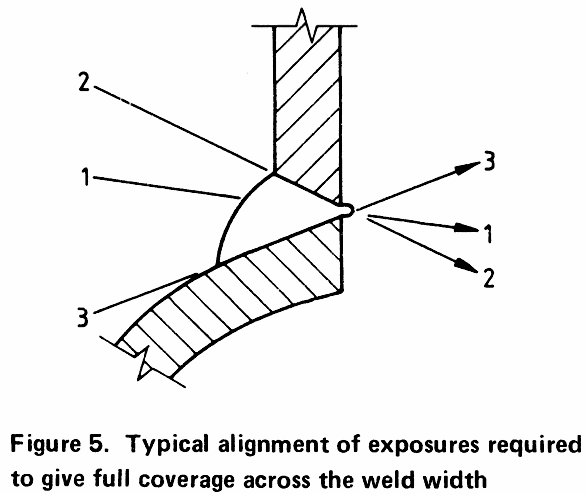

I was radiographing a steam-pipe taken from a marine engine-room for investigation. Looking at a smaller-diameter side-branch welded to the main steam pipe being investigated - do you need to do more than one shot of the same feature & location from the same general direction? More explanation follows later.

The answer is Yes. In BS7257:1989 - withdrawn!

The full title of British Standard BS7257:1989 (withdrawn) is "Radiographic examination of fusion welded branch and nozzle joints in steel". So this is the topic I was considering.

Some explanation of the issue.

Radiography will only detect planar / crack-like defects if the imaging radiation is edge-on to the crack. So you have to consider where such defects might be and what inclination they might have. Then arrange a shot where the illuminating radiation is shining along that inclination / direction.

Knowing welding, a viable proof of fitness for purpose would need to show that the fillet-weld-like fusion of the weld-metal to the main steam pipe was indeed fully fused. If it were not, you'd have a crack-like defect presented along the still-existing tube surface. So you need to rake the radiation in parallel to the tube surface at the location of the side branch in one shot. That is "Shot 3" in the image from BS7257. "Shot 1", the "general volume" shot is needed. "Shot 2" - you are less likely to have lack-of-fusion defects there as the heat is not being so rapidly abstracted down the smaller side-branch pipe. So a professional judgment might be that "Shot 2" is not required in this case.

BSEN1435:1997 "Non-destructive testing of welds - Radiographic testing of welded joints" is a very practical guideline and framework for doing radiography. Fit within the clauses and quantities and you can have a "BSEN1435 radiograph". However, what with all the clauses so bounding the issues, BSEN1435 becomes a method of shooting radiographs.

What seemed to me was that there is great aesthetic beauty to BSEN1435. Between first seeing this fairly brief document and fully understanding it is a hard-work path, but there is a sparse perfection about it which dawns on you as your understanding of radiography grows. It gives the impression of a work of a peer-group of committed professionals with a deep liking for their subject.

While receiving initial training in Radiography, I was traveling by train, to give myself reading time. So I was coupling my training in shooting radiographs to reading and understanding BSEN1435. The nature of the reading was to read BSEN1435 beginning-to-end repeatedly, understanding more detail at each pass. This is often referred to by the analogy, "peeling the layers of an onion". The document is quite short, but what it says is very concentrated, and you peel back layer after layer of deeper and deeper understanding.

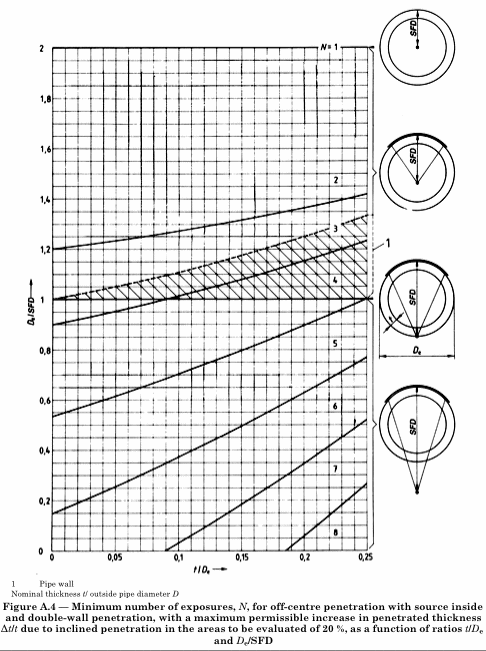

The following diagram typifies BSEN1435:

It's taken out of context of the whole document. However, the thing is that the document fits together as a coherent terse whole.

I can assure you it came to me in stages over days. Initially it seemed "double-Dutch". But then I came to realise it was a piece of perfection, as it gathered a vast amount about related situations into one coherent diagram.

At its simplest level though, if you have a pipe and know its diameter and thickness and where you are going to put your radiation source, you can read off how many shots equally spaced around the pipe you will need for a "BSEN1435 radiograph".

As you understand it more, you being to understand other parts of the standard.

A specially advantageous case I encountered early on, radiographing one of my own pipe-welds. If you can put your radiation source at the centre of the pipe (a "panoramic" shot):

It is well-know in radiography. In general, with no other information provided, one can say with overwhelming probability whether a radiograph as seen is from an X-ray shot or a Gamma shot.

This is because X-ray shots are usually very sharp and contrasty, looking a lot like an optical-camera photo negative, whereas Gamma shots tend to be more fuzzy and low on contrast ("flat").

However, Radiography presents many interesting twists and turns dependent of the most pragmatic of practicalities.

Apropos of nothing, I spotted this clause in BS7257:1989 (withdrawn).

B.1.4 Where these is a choice between gamma-ray source single-wall and X-rays double wall, single image, the former is preferable for the following: (a) penetrated thickness above 2mm and below 12mm using a 169Yb source; (b) penetrated thickness between 12mm and 25mm using a 192Ir source.

Because an X-ray tube is a great big thing, you often can't get the X-ray tube into the inside of the pipe. So the only way to get the shot would be to send the radiation through the far wall of the structure on its way to image the weld of interest. Which degrades the image quality.

Whereas a Gamma source is a tiny little thing and you can get it into many tight spaces.

The clause is about Gamma wins out giving a better image in the quoted range of circumstances where the Gamma source can go inside the pipe and joint bore and shine direct from the source through "thin air" and the weld of interest to the imaging film. Where in that circumstance X-ray imaging radiation would have to plough through an unnecessary extra steel wall thickness.