Abbreviations:

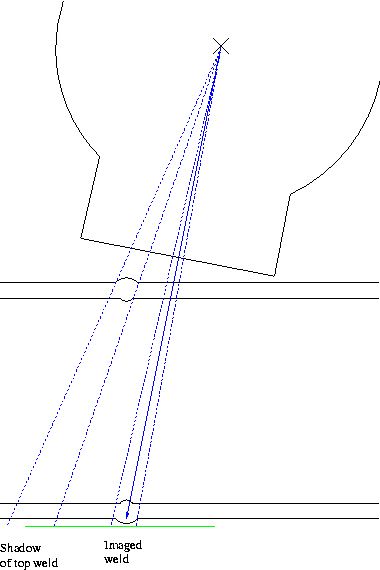

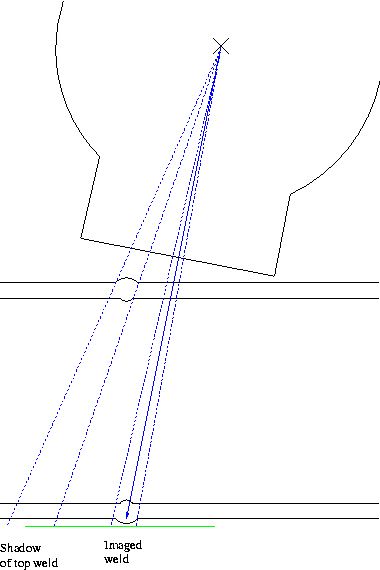

You can go for the "ellipsing angle" (as in for DWDI-ellipse) and get a very visually pleasing radiograph

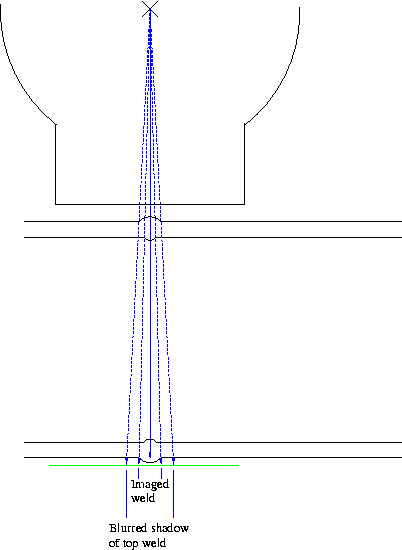

Or you can shoot "square on" / perpendicular straight through the top weld - getting a uniform diffuse blurred shadow of the source-side weld over and bordering the image of the image-side weld (similar to DWDI-si but source-side weld out-of-focus).

The advantage with shooting perpendicular, straight through the top bead, is that the imaging radiation would be parallel / "end-on" to any through-thickness planar defects - cracks, hot tears, Lack of Root Fusion "cold lap", etc. Which you would be supremely interested in imaging if they exist...

Comparing this to the "ellipsing angle" approach of throwing the source-side weld image completely clear of the imaged weld and the inspected HAZ: The "ellipsing angle" of 1:5 is an imaging radiation angle of 11.3degrees. So a through-thickness crack would not image. The rule-of-thumb is that a crack will not image on a radiograph if the imaging radiation is more than 8degrees off the crack axis. So the defect whose presence would be most dangerous and which you most want to detect if it were there would not be seen.

So the second one - shoot perpendicular, straight through the opposite weld, has advantages even though you get a less visually pleasing radiograph.

Apparently, PCN say you must "ellipse" and throw the source-side weld

image to the side when doing an X-ray DWSI in their exams.

From a private conversation with an examiner. Check this yourself.

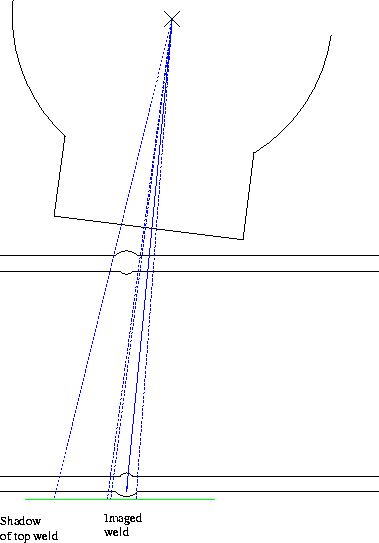

Putting the source "just beside the opposite weld" is often advocated for Gamma-source shots. Because of the recess of the X-ray tube target from the beam port of the X-ray tube, you don't want to be positioning the X-ray head to send the centre of the X-ray beam through that location. The recessing of the target from the beam port means you do get a blurred dark-shadow image of the source-side weld. You'd throw that curved dark shadow part over the weld and definitely onto one side parent metal but not the other side parent metal. On the weld image, at the to-the-edges locations where the shadow does fall over the imaged weld it'll be too dark and in the middle where the shadow just throws clear it'll be too light. Not useful.

Due to the through-thickness crack imaging issue, you might question whether you'd want to put the Gamma source right on top of the source-side weld-bead. The top weld would be completely "blown away" and not imaged due to the source centre being only about 5mm above the source-side bead, with a source of about 2mm to 4mm size and 10's of mm to go onward to the imaged side weld. The angle from a gamma-source "just beside the source-side bead" is about 4deg to 4.5deg - so through-thickness cracks should image, but you'd be advantaging things being fully perpendicular.

These sketches show the overall appearance of the radiographs produced by the different geometries of DWSI shots discussed.

R D Smith, 18 July 2010, 22 August 2010