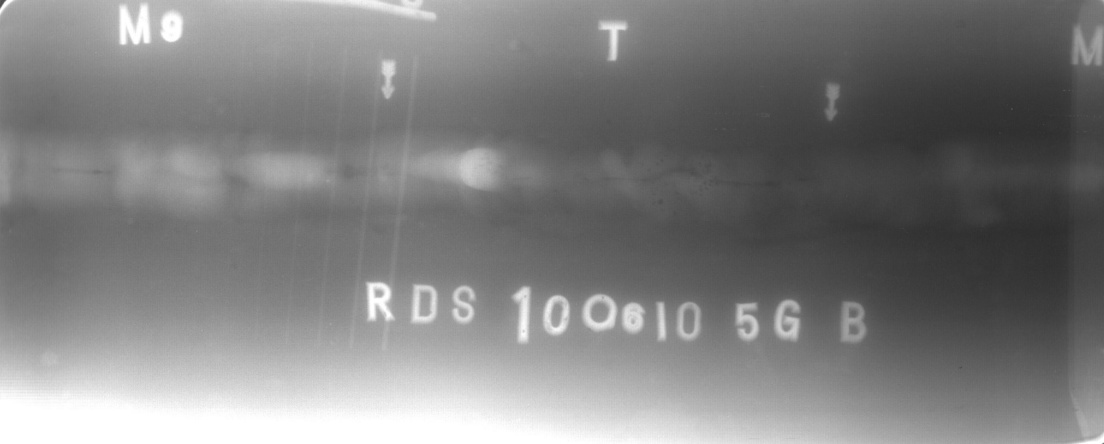

Pipe is 140mm outside diameter (OD), 10mm wall-thickness. Welded SMA all-Basic (7016 root; 7018 hot-pass, fill and cap).

Positioned IQI's in bore

By final clause of section 6.6 favouring panoramic shots with shorter allowable minimum source-to-film distance, seems that despite "small" tube size, this may be a fully compliant BS EN 1435 radiograph.

The Radiographs are very revealing - I have received much guidance on my welding technique from what could be diagnosed.

Best scans managed of the radiographs on a general-purpose scanner - lacking the fine resolution of the originals viewed on a radiograph viewing screen.

Note - the weld-prep is "wavy" as the tube was manually plasma-cut into two pieces and the ends bevelled "as is" - which gives a wavy root but which matches up with uniform gap.

{30 June 2010 - I can now identify these faults with radiograph, when working to BS EN 1435:1997 / Class A

Also - the arrows should not be there. Unnecessarily sub-division

mark the radiograph. And they confuse given the conventional meaning

of the limits of examinable region in a shot.

However - granting all this - still very informative first ever own radiograph!

Ignoring all surface features (incomplete root penetration, "icicles",

burn-through, etc) evident in the radiographs - abundantly so! - and

in the photographs!

These surface defects will change with weld conditions modified

regarding any in-volume weld defects identified, so now is not the

time to consider these surface defects.

Interpretation - all credit to a couple of experienced welder / radiographers: the porosity plus my answers to questions lead to identifying that I am not running my welding rods hard enough - at high enough current (Amps). This points to a welding condition I already see in 2G, with a fluid properly-formed weld-pool. This means that in future practice doing 5G welds I will only be interested in obtaining that appearance of weld pool irrespective of what Amps the welding machine's current setting claims.

(R D Smith, 11.06.10, 30.06.10)