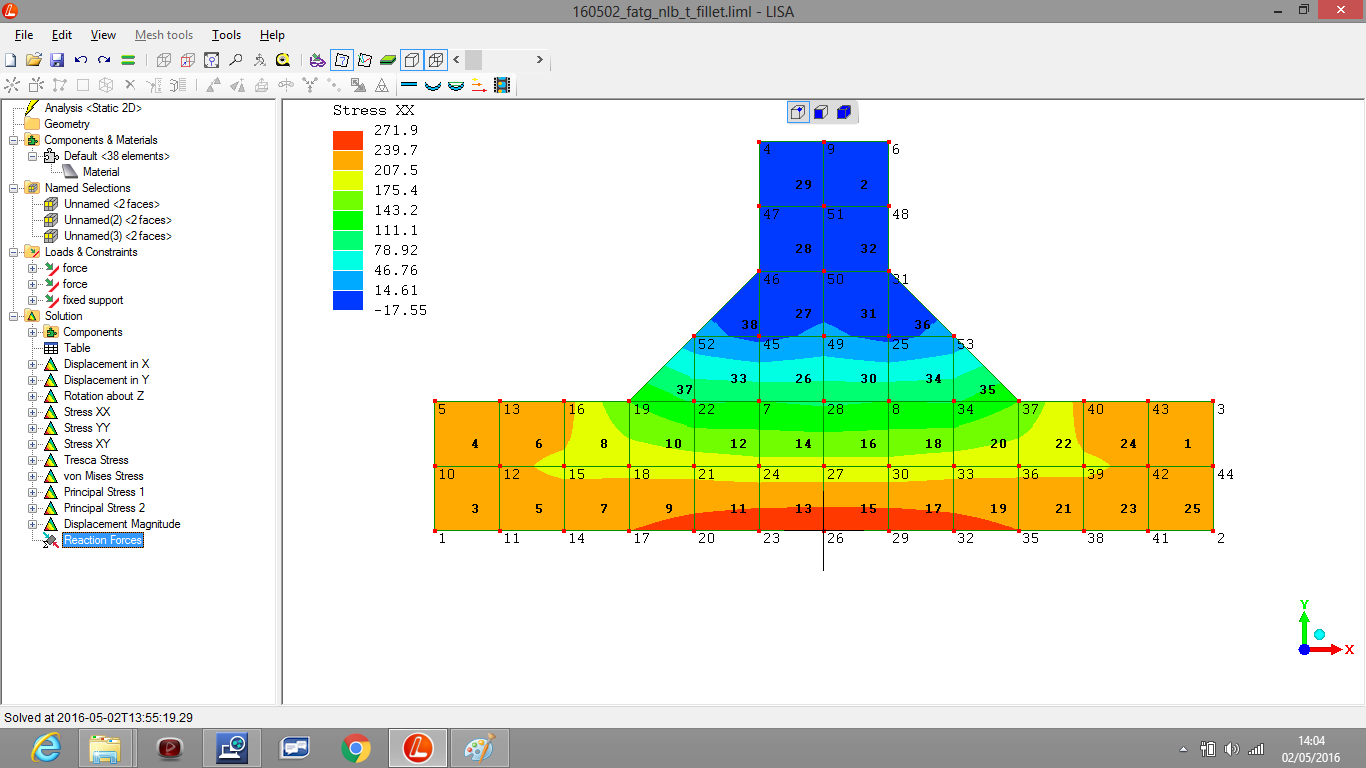

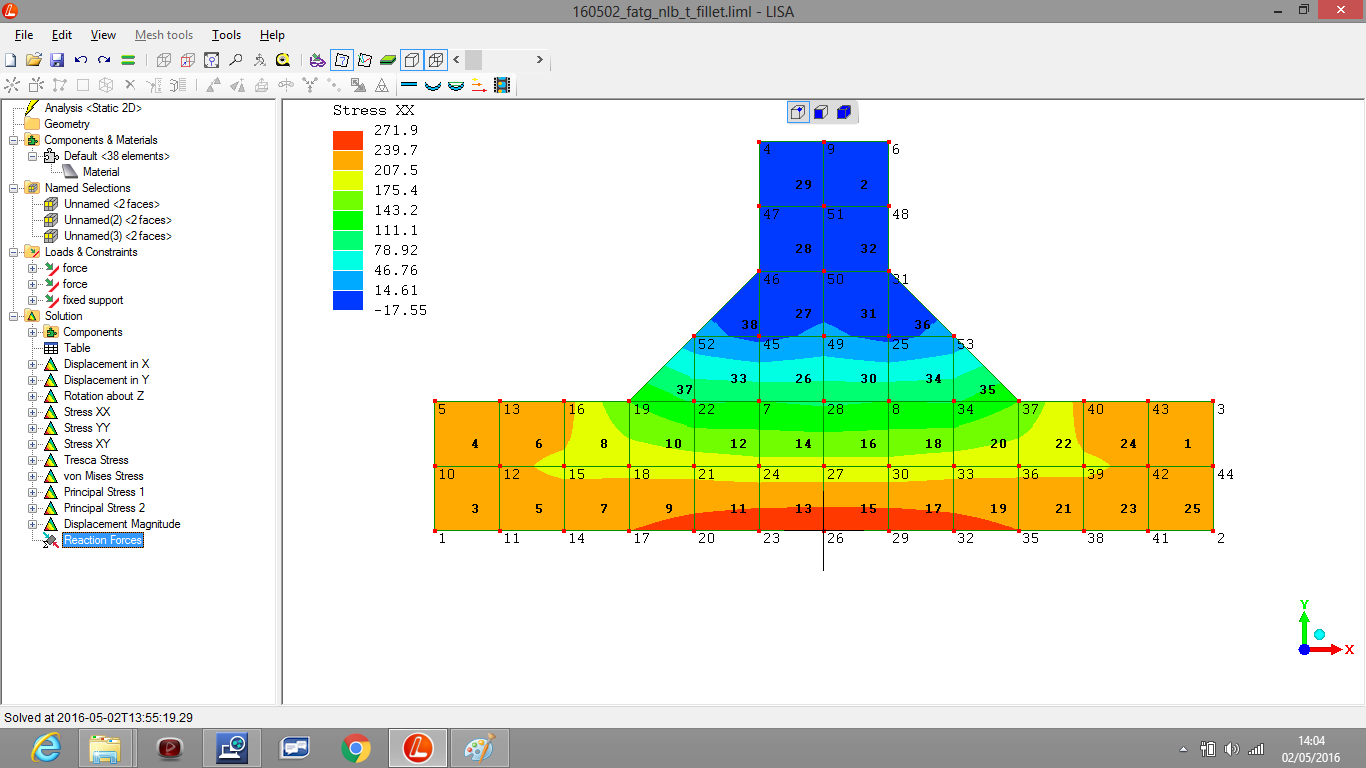

I can hardly start to list why you should not take these simulations seriously.

Just look at the pictures for their "beauty" and think of what it

meant to me getting the program to respond in my first ventures away

from step-by-step tutorials.

There's quite a number of steps before the "solver" will accept your

model and produce a non-null output.

The "small steps" are happening...!

For what it's worth

If there is an interesting thought from looking at this;

it's that the load is producing an bending away from the terminating /

intersecting plate, which is placing the unwelded side of the joint in

much higher tension while reducing the stresses near the weld. That

should be advantageous for fatigue-resistance - as fatigue failures

are mainly around welds. However - this observation does not match

what is seen in real life - welds fail by fatigue and one does not get

the impression that anything is "protecting" the weld from those

stresses.

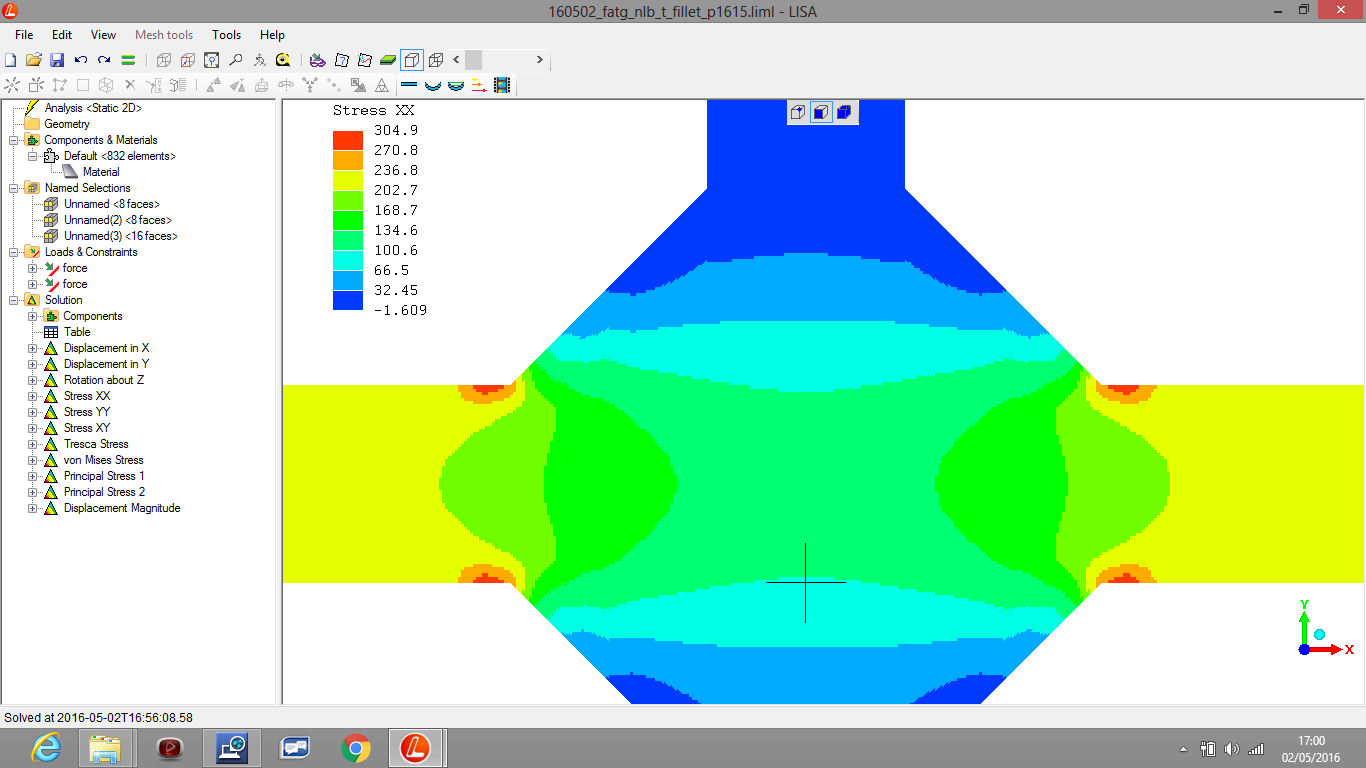

I've "cranked-up" the discretisation, making the finite-element mesh finer, for a more resolved, accurate, result.

I've "mirrored" the original weld, producing this entire "X"-joint

which is modelled in full. This form is balanced with zero bending

moment in relation to applied forces along the "main plates" (the

structural members reaching out left-and-right (hand sides)).

In order to just look at stress concentrations around the "fillet-weld

toe".

That's a very improvised way of getting around that I didn't yet know

how to create a plane-of-symmetry in a FEA model

(so it's as if the model had the "mirrored" part, for all its physical

effects - but you don't expend computer resources simulating it - so

you can concentrate your computing resources on the half which is

actually modelled)

Leave these for now and forget about them.

I'm trying to walk before I can crawl!

(R. Smith, 17May2016)