I suggest these results are inclusive.

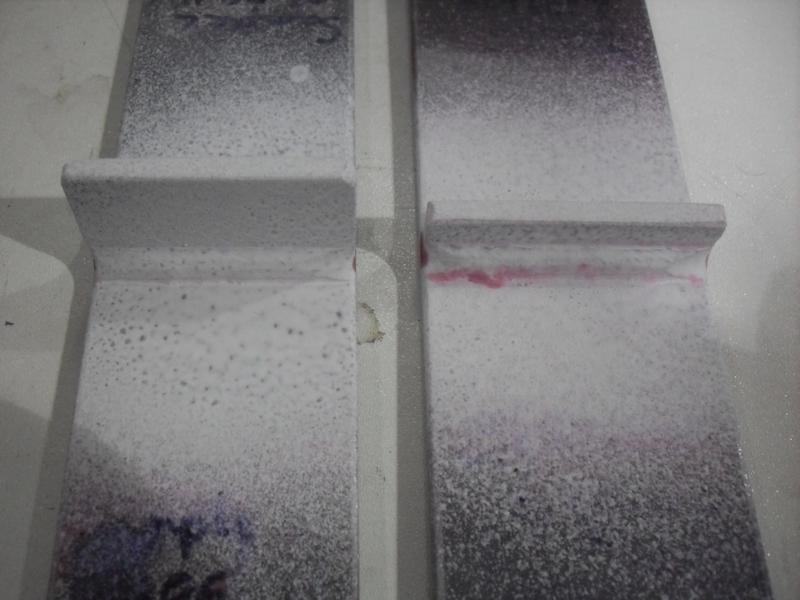

I reckon there is just about an indication on the sample on the right-hand-side with "Sample 2 - 03.06.11" showing. A line of indication which is narrow and fairly sharp at the weld toe - plate to fillet. It doesn't really show on photograph. Any other colouring is dismissed as spurious on the basis of being too faint and spread-out.

In all honesty I am looking for an indication at the weld toe. Realistically however, this test procedure is unconvincing.

The dye-penetrant system is solvent-based, using aerosol spray cans (cleaner, dye and developer). I was told many years ago that solvent-based is best for machined surfaces and water-based is best for welds.

To avoid spurious faint dye everywhere I had to spray solvent on the sample and wipe clean after the dye stage. Which is a more severe clean than the recommended wipe with solvent-damped cloth.

Point is - wouldn't like to suggest any comment on capability of DPI, as this is rather quick impromptu try.

It was suggested as not a good idea to try to DPI samples in the fatigue tester, as the fluids used would get into the grips and act as a lubricant. The argument seems reasonable. It implies DPI is not suitable for the more interesting task of trying to monitor fatigue crack growth during the testing.

R D Smith 18.06.11